Refineries

We have been supplying pumps and systems for distillation plants for processing crude oil for 60 years. Ask our experts for more information!

Read more

LEWA pumps are used in a wide variety of processes for the production of biodiesel and other biofuels.

Depending on the particular application, different pumps that optimally meet the respective requirements are used:

LEWA pumps in various processes for biofuel production:

| Illustration | Process description | Process |

|---|---|---|

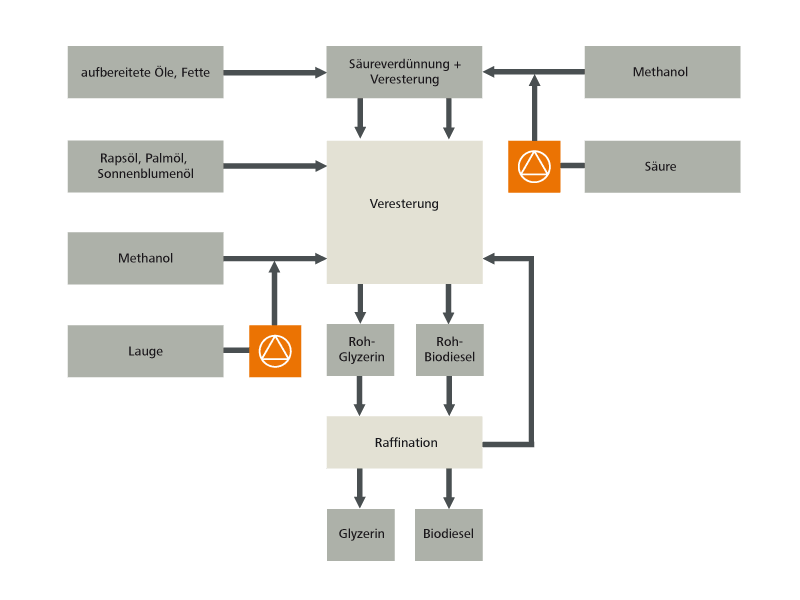

| Conventional process for biodiesel production: Esterification of vegetable oils with methanol. | Low pressure 1st generation |

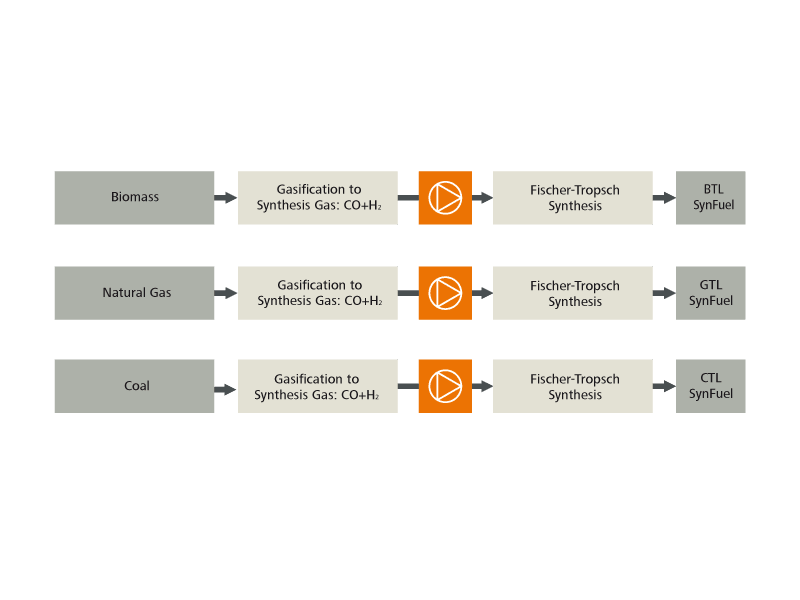

| Alternative process for synthetic fuel production: Gasification of carbon-containing raw materials for the production of synthetic gas (CO+H2), which is subsequently converted into a long-chained fuel using Fischer-Tropsch synthesis. In the last process step (hydrocracking), the desired BTL fuel (synfuel) is generated at temperatures < 200°C and a process pressure up to 90 bar.  For more information about this, visit: www.bioliq.de For more information about this, visit: www.bioliq.de | High pressure 2nd generation |

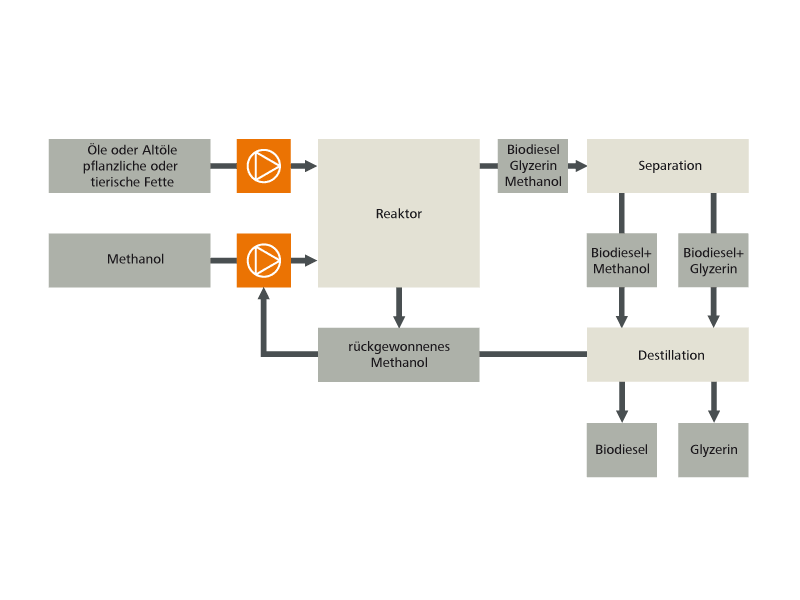

| Similar process (conventional) Esterification of organic fats or oils with methanol in a high-pressure process. | High pressure 2nd generation |

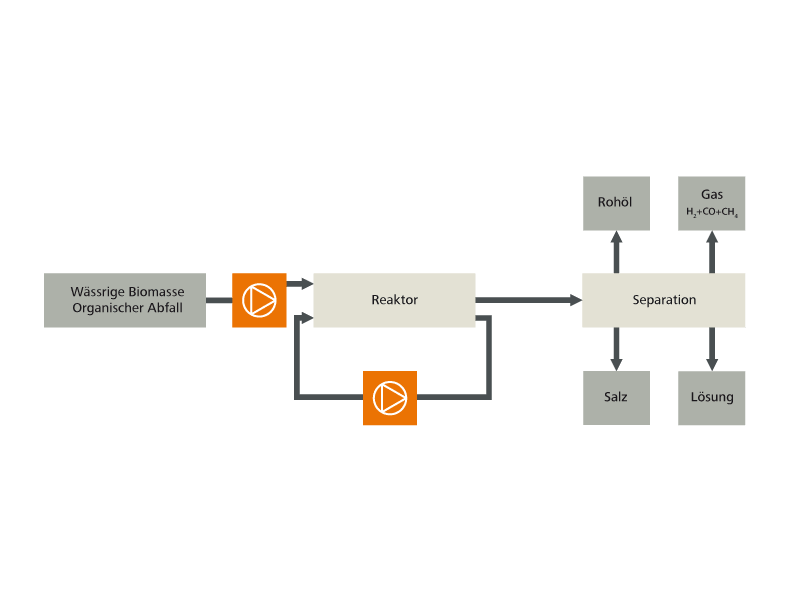

| Thermal decomposition of organic waste for the production of crude oil with a low boiling point as well as gas with a high hydrogen content. | High pressure 2nd or 3rd generation |

The use of biofuels offers significant advantages in comparison to fossil energy sources:

Biofuel production 1st generation

Vegetable-oil-based fuels:

| Source | Fuels | Targets |

|---|---|---|

Oil-bearing plants from agriculture production:

|

|

|

Bioethanol:

| Source | Fuels | Targets |

|---|---|---|

Renewable resources

|

|

|

Legend:

| Term | Description |

|---|---|

| Biofuels: Synfuels: BTL: GTL: CTL: CNG: LPG: ETBE: FAME: RME: | Renewable fuels and propellants Designer fuels Biomass to liquid Gas to liquid Coal to liquid Compressed natural gas Liquefied petroleum/propane gas Ethanol tertiary butyl ether Fatty acid methyl ester Raps methyl ester |

Biofuel production 2nd generation

Synthetic fuels (synfuels):

| Source | Fuels | Targets |

|---|---|---|

Gasification of renewable resources, biogenic and renewable residual materials:

|

|

|

Biofuel production 3rd generation

Hydrogen:

| Source | Fuels | Targets |

|---|---|---|

| From biomass through thermochemical and microbiological processes as well as from electrolysis, powered by photovoltaic systems and wind power plants. |

|

|