Oil & Gas

You can rely on 60 years of experience in the construction of pumps, packages, skids, and systems for onshore and offshore oil and gas production. Take a look at the information now!

Read more

Conventional pump systems, such as piston or centrifugal pumps, can be reliably operated for the injection of hydrogen sulfide/carbon dioxide only by using expensive additional measures. Process diaphragm pumps from LEWA are a reliable solution for these pumping tasks up to outputs of 1000 kW. If two coupled pumps running in parallel are used, this extends to well above 1000 kW.

H2S (acid gas) is an extreme challenge for pump systems:

The most important properties of the LEWA process diaphragm pumps for critical applications such as CCS are:

To optimize the energy efficiency in the CSS compression, for example, a combination of compressors and process diaphragm pumps is recommended.

In order to optimize the energy efficiency during the injection, a combination of compressors and process diaphragm pumps is recommended.

Read more in our technical article

CCS Compression with compressors and process diaphragm pumps

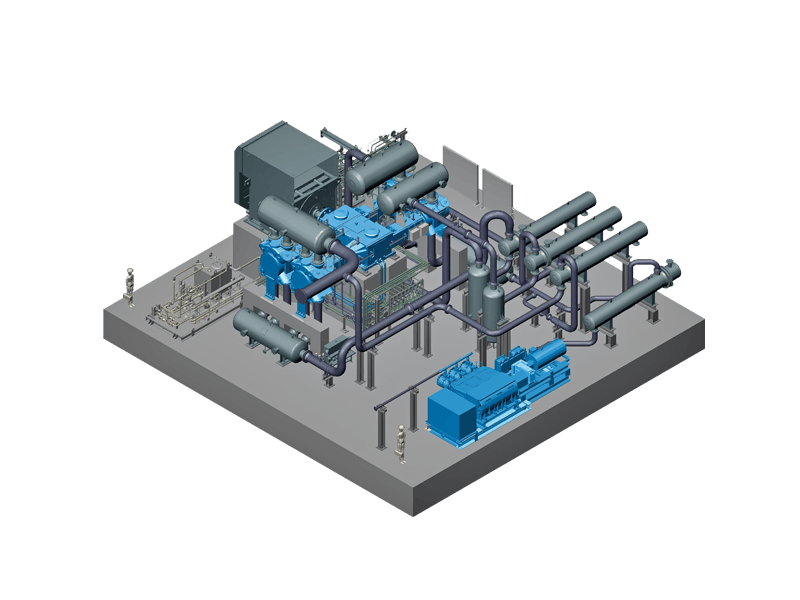

Example: System for injecting CO2, 3-stage reciprocating compressor with triplex diaphragm pump.

Process description

Hydrogen sulfide is a compound of sulfur and hydrogen with the chemical formula H2S. It is flammable, colorless, toxic, and smells like rotten eggs. It is a weak acid, whose salts are sulfide and hydrogen sulfide.

In nature, hydrogen sulfide occurs as a very variable component of natural gas and crude oil, as volcanic gas, and in spring water. It also results from rotting and decomposition processes during the breakdown of biomass, at waste disposal sites, or in high pressure wastewater pipelines.

Source: Wikipedia, February 2012