Cleaners & Detergents

We offer reliable, formula-controlled systems for the production of cleaners and detergents. Ask the LEWA experts for more information now!

Read more

Plant concept

1. Features:

2. Equipment:

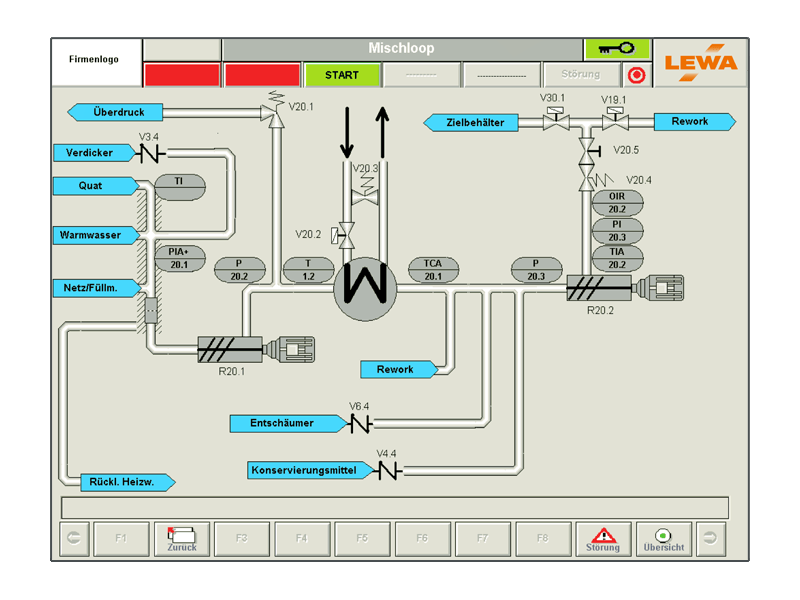

Example: System control - Illustration of process step "surfactant dilution"

LEWA supplies the entire system from a single source:

Design, engineering, construction and delivery of the system, scope of service on request, complete with:

The most important variables influencing pricing are:

Process description

During the production of fabric softener, the concentrate, warm water, and thickener are blended in the first dynamic mixer. After the addition of cold water, the product passes through a static mixer and then through a heat exchanger for cooling. Then the "finishing components" are metered according to the recipe and the entire mixture is passed through another mixer.

Any product produced during start up and cleaning or when changing to another recipe and that cannot be used is discharged via a 3-way valve into a rework tank and added back into the process immediately or later, via a separate pump. Typical production units have production capacities starting at 5 tons/hr.