Universal applicability for large flow rates

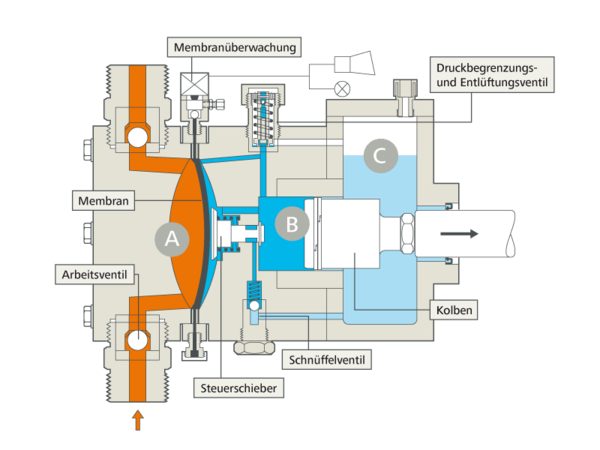

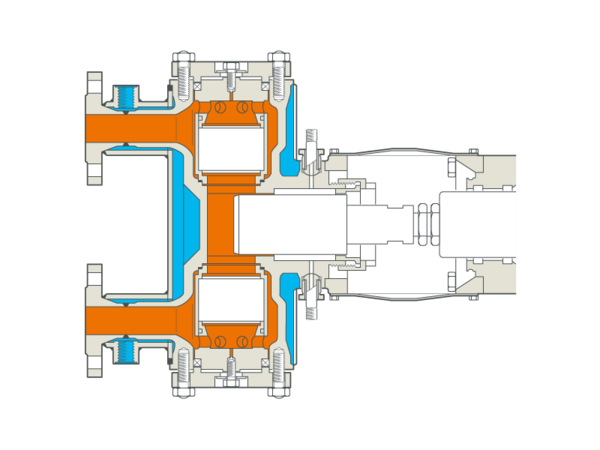

pump head M500

The LEWA M500 is a pump head with a hydraulically actuated diaphragm made of pure PTFE for universal use. It is mainly used for large flow rates on LEWA process pumps.

- Hermetically sealed – no leaks of pumped fluid or hydraulic oil

- High metering accuracy

- Long diaphragm service life

- Secure against misuse and against impermissible operating states, which results in outstanding system availability.

- Universal use thanks to freely oscillating diaphragm – resistant to dirt or particulate in the pumped fluid. It is also suitable for suspensions

- Continuous diaphragm monitoring which enables downtimes to be planned

- Maintenance-free plunger seal using piston rings or ground bushings

- Special designs for highest temperatures

Technical data

| Type | Maximum pressure | Maximum flow rate for each pump head | Temperature | Maximum viscosity |

|---|---|---|---|---|

| M500 | 350 bar | 19 m³/h | -50/+150 °C | 100,000 mPa∙s |

Function

The M500 is divided into 3 chambers: The fluid is pumped through chamber A. Chamber B is the hydraulic pressure chamber and contains the hydraulic fluid. Chamber C is used as a reservoir for the hydraulic fluid and is depressurized. The multi-layer diaphragm (also called sandwich diaphragm) separates Chambers A and B and is simultaneously used to seal Chamber A and B from the atmosphere. Since it is a static seal, the pump head can be considered hermetically sealed. The condition of the multi-layer diaphragm is monitored continuously. Chambers B and C are separated by a piston and multiple hydraulic valves.

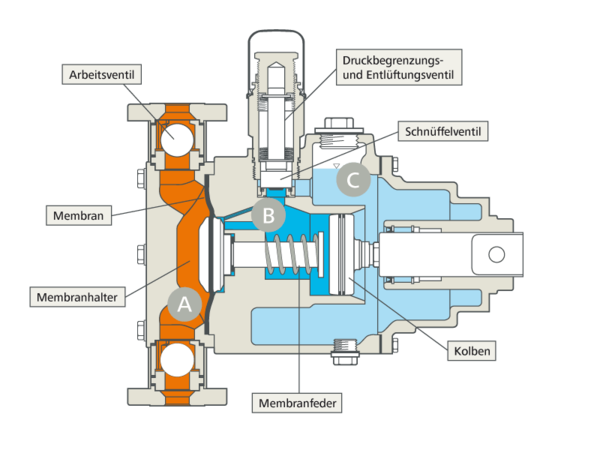

The pump head for medium flow rates

Pump head M900

The LEWA M900 is a pump head with a hydraulically actuated diaphragm made of pure PTFE with a diaphragm holder made of stainless steel. It is designed for universal application. It can be used on all LEWA ecoflow pumps and with average flow rates on LEWA process pumps.

- Hermetically sealed – no leaks of pumped fluid or hydraulic oil

- High metering accuracy

- One-of-a-kind suction capacity via the diaphragm spring

- Very long diaphragm service life

- Absolutely secure against misuse and against impermissible operating states, which results in outstanding system availability.

- Universal use thanks to freely oscillating diaphragm – resistant to dirt or particulate in the pumped fluid. It is also suitable for suspensions

- Continuous diaphragm monitoring which enables downtimes to be planned

- Maintenance-free plunger seal using piston rings or ground bushings

- Special designs for highest temperatures

Technical data

| Type | Maximum pressure | Maximum flow rate for each pump head | Temperature | Maximum viscosity |

|---|---|---|---|---|

| M900 | 500 bar | 6 m³/h | -20/+150 °C | 100,000 mPa∙s |

Function

The M900 is divided into 3 chambers: The fluid is pumped through chamber A. Chamber B is the hydraulic pressure chamber and contains the hydraulic fluid. Chamber C is used as a reservoir for the hydraulic fluid and is depressurized. The multi-layer diaphragm (also called sandwich diaphragm) separates Chambers A and B and is simultaneously used to seal Chamber A and B from the atmosphere. Since it is a static seal, the pump head can be considered hermetically sealed. The condition of the multi-layer diaphragm is monitored continuously. Chambers B and C are separated by a piston and multiple hydraulic valves.

LEWA Series M800 diaphragm pump heads are, in principle, designed like the pump heads of the tried-and-tested M500 series. These are pump heads with a freely oscillating PTFE diaphragm and diaphragm position control via a control push rod.

The special feature of this series is the very high level of permissible operating pressure. Pump heads of the M800 series can be used for discharge pressures up to 1000 bar.

One of the greatest challenges in developing high pressure pump heads is the diaphragm clamping system. Due to the design of the patented solution developed by LEWA, the clamping position does not “breathe” during the discharge stroke.

This has been implemented using an indentation that is formed by a circumferential flexible lip in the area of the diaphragm clamping system. This geometry, calculated using the finite element method (FEM), leads to a completely different movement behavior of the clamping system (specifically: there is no negative axial movement in the two halves of the clamping position relative to one another).

With this modified movement behavior, the PTFE diaphragm can have a long service life, even at very high pressures. As a result of the M800 pump head, LEWA is the only pump manufacturer that works with a PTFE diaphragm at pressures ranging from 400 to 1,000 bar.

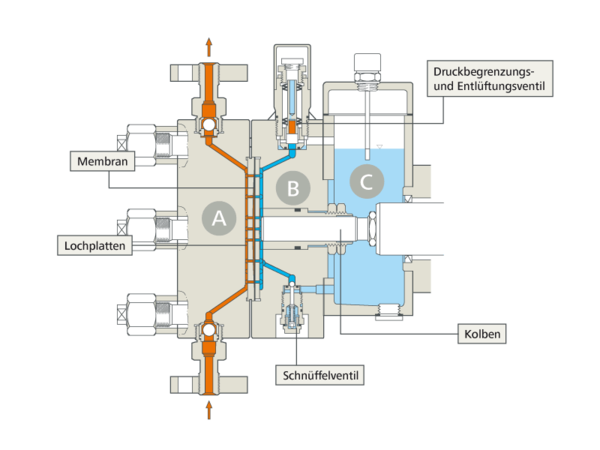

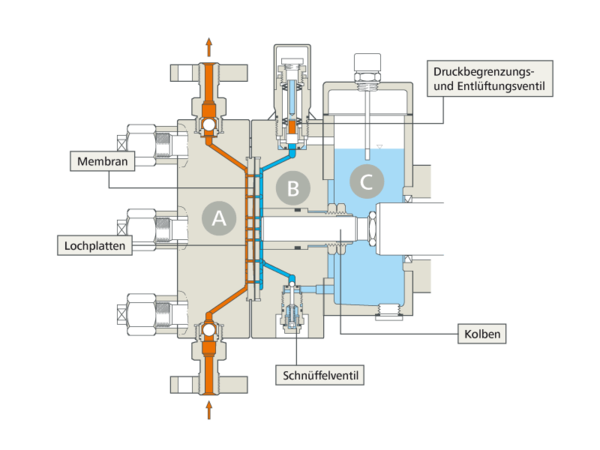

Reliable at high pressures

Pump head M800

LEWA Series M800 diaphragm pump heads are, in principle, designed like the pump heads of the tried-and-tested M500 series. These are pump heads with a freely oscillating PTFE diaphragm and diaphragm position control via a control push rod.

The special feature of this series is the very high level of permissible operating pressure. Pump heads of the M800 series can be used for discharge pressures up to 1000 bar.

One of the greatest challenges in developing high pressure pump heads is the diaphragm clamping system. Due to the design of the patented solution developed by LEWA, the clamping position does not “breathe” during the discharge stroke.

This has been implemented using an indentation that is formed by a circumferential flexible lip in the area of the diaphragm clamping system. This geometry, calculated using the finite element method (FEM), leads to a completely different movement behavior of the clamping system (specifically: there is no negative axial movement in the two halves of the clamping position relative to one another).

With this modified movement behavior, the PTFE diaphragm can have a long service life, even at very high pressures. As a result of the M800 pump head, LEWA is the only pump manufacturer that works with a PTFE diaphragm at pressures ranging from 400 to 1,000 bar.

- Very high operating pressure while simultaneously using the freely oscillating PTFE diaphragm

- As a result of the lowest possible use of materials, LEWA is able to offer inexpensive options in the high pressure range (small outer diameter compared to diaphragm pump heads made of metal; no perforated plates)

- Hermetically sealed – no leaks of pumped fluid or hydraulic oil

- High metering accuracy

- Long diaphragm service life

- Secure against misuse and against impermissible operating states, which results in outstanding system availability.

- Universal use thanks to freely oscillating diaphragm – resistant to dirt or particulate in the pumped fluid. It is also suitable for suspensions

- Continuous diaphragm monitoring which enables downtimes to be planned

- Maintenance-free plunger seal using ground bushings

Technical data

| Type | Maximum pressure | Maximum flow rate for each pump head | Temperature | Maximum viscosity |

|---|---|---|---|---|

| M800 | 1,000 bar | 1 m³/h | -10/+60 °C | 100,000 mPa∙s |

Function

The M800 is divided into 3 chambers. The fluid is pumped into chamber A. Chamber B is the hydraulic pressure chamber and contains the hydraulic fluid. Chamber C is used as a reservoir for the hydraulic fluid and is depressurized. The multi-layer diaphragm (also called sandwich diaphragm) separates Chambers A and B and is simultaneously used to seal Chamber A and B from the atmosphere. Since it is a static seal, the pump head can be considered hermetically sealed. The condition of the multi-layer diaphragm is monitored continuously. Chambers B and C are separated by a piston and multiple hydraulic valves.

Stainless steel diaphragm for special requirements

Pump head M200/M400

The LEWA M200/M400 is a pump head with a hydraulically actuated diaphragm made of stainless steel (or of other high-quality materials like Hastelloy or titanium). It is used in places where diaphragms made of plastic can no longer be used:

- Extremely high operating pressures possible

- Extremely high operating temperatures possible

- Absolutely diffusion-resistant

Technical data

| Type | Maximum pressure | Maximum flow rate for each pump head | Temperature | Maximum viscosity |

|---|---|---|---|---|

| M200/M400 | 1,200 bar | 0.8 m³/h | -40/+200 °C | 500 mPa∙s |

Function

The M200/M400 is divided into 3 chambers: The fluid is pumped into chamber A. Chamber B is the hydraulic pressure chamber and contains the hydraulic fluid. Chamber C is used as a reservoir for the hydraulic fluid and is depressurized. The diaphragm (usually as a multi-layer diaphragm) separates chambers A and B and is simultaneously used to seal chamber A and B from the atmosphere. Since it is a static seal, the pump head can be considered hermetically sealed. The condition of the multi-layer diaphragm is monitored continuously. Chambers B and C are separated by a piston and multiple hydraulic valves.

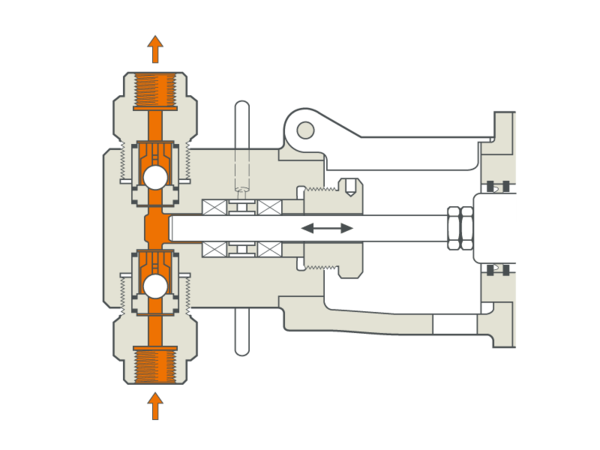

For straightforward applications with plunger pumps

Pump head K110/K111 - K210/K211

The piston displaces the conveyed fluid directly in plunger pumps. Pistons and plunger seals are wetted. A high degree of operational reliability is achieved as a result of the suitable piston materials and seal design.

- Durable and simple structure

- High metering accuracy

- Long piston service life and plunger seal due to movable pistons and the selection of material for each individual application

- LEWA piston pump heads require only low maintenance effort

The selection of plunger seals is made depending on fluid, pressure and temperature. Plunger pumps are preferably used with simple, unproblematic fluids.

Special designs, e.g., with a complete heating jacket for melting, are available. The use of diaphragm pump heads is recommended for critical, abrasive, toxic, or flammable fluids.

- K110/K111: Standard pumping heads with simple stuffing box

- K210/K211: High pressure pump heads with special stuffing box

- K511: Special design with complete heating jacket for melting.

Technical data

| Type | Maximum pressure | Maximum flow rate for each pump head | Temperature | Maximum viscosity |

|---|---|---|---|---|

| K110/111 K210/211 | 500 bar | 9 m³/h | -70/+400 °C | 1,500,000 mPa∙s |

| K511 | 176 bar | 1.5 m³/h | -20/+150 °C | 100,000 mPa∙s |

Function

All LEWA plunger pump heads work according to the displacement principle. The piston suctions the metered fluid directly and displaces it into the discharge line. The plunger seal is designed as a dynamic seal in the form of a clamped stuffing box or with profile sealing rings. The process valves open through the pressure change in the pump head and close by the gravity of the moved valve body or by spring force.