Cleaners and detergents

precise, formula-controlled systems with LEWA

LEWA offers continually operating, formula-controlled systems for the manufacture of household and industrial cleaners in all commercially available surfactant concentrations – from raw product to end product.

We use surfactants as the main active ingredients as they have special properties. Each molecule has one hydrophobic and one hydrophilic end. LEWA also supports surfactant production and processing. You can find more detailed information about this in our Chemical industry description and in the example application Systems for surfactant processing.

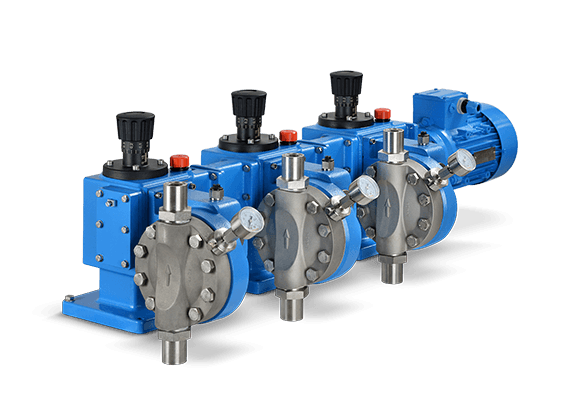

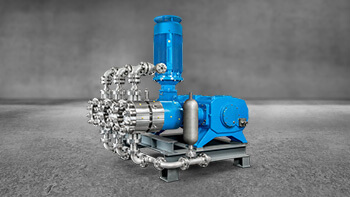

LEWA Pumps and Systems In the Manufacture of Detergents and Cleaners

Our experts are on hand with help and advice and will work with you to develop custom systems and plants for manufacturing cleaners and detergents. You can rely on our many years of industry expertise.

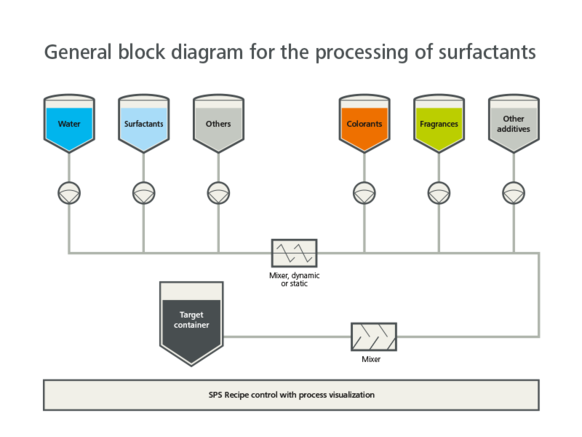

The diagram shows you the basic illustration of a surfactant processing system.

We especially focus on the typical process steps during the manufacture of detergents and many other end products with LEWA pumps and systems.

| Example process steps | Examples of end products |

|---|---|

|

|

Solutions for the Manufacture of Cleaners and Detergents

We work with you to plan and implement fully automated and formula-controlled systems and assist you during the switchover from batch to continuous processing.

The development of the concept, engineering, construction, and delivery of the detergent production system, as well as the process steps including instrumentation, control systems, and automation: everything comes from a single source. Even after commissioning, we support you with comprehensive services, for example in process technology, we offer assistance during process optimization, mechanical maintenance and repair, or with instrumentation and control technology.

Advantages at a Glance

High end pumps, equipment and systems

We deliver high-end pumps integrated into complete systems and units for your specific applications. In doing so, we of course rely on the tried-and-tested LEWA quality.