Food & Beverage Industry

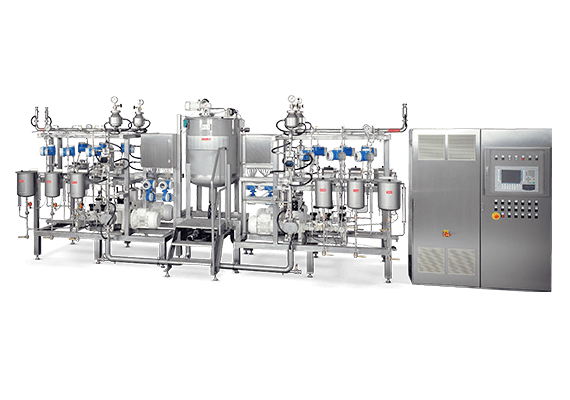

Precise System Solutions for Hygienic Processes with LEWA

Process integrity, recipe compliance, and product reliability are basic prerequisites in food technology. Hygienic aspects and cleanability play a central role: The process must remain closed and contamination of the process media must be prevented in every phase of production.

LEWA supplies precise system solutions in the manner in which they are required in the food and beverage industry for processes such as homogenization, mixing, and filling.

Areas of Application for LEWA Pumps and Systems in the Food Industry

Our products allow you to convey and meter, as well as process and homogenize.

| Product applications | Typical tasks | Examples of subindustries |

|---|---|---|

| Areas of application for our products and solutions in the food and beverage industry | Conveying low-viscosity and viscous media |

|

| Proportionally metering additives, e.g., flavorings, acids, vitamins, color pigments, in a precise and controlled manner |

| |

| Mixing/dispersing/homogenizing |

| |

| Filling |

| |

| Tempering |

| |

| Spraying for drying and preparing food under medium to high pressure |

| |

| Treating with SO2, O2, and preservatives |

| |

| Extraction, e.g., with CO2 |

| |

| Coatings |

|

Customers who use our pumps and systems convey, meter, and process a multitude of substances for the production of foods and beverages.

| Substance | Examples of end products | |

|---|---|---|

| Typical substances that we convey, meter, and process | Gelatin, chocolate |

|

| Sugar, glucose mixtures |

| |

| Waxes, wetting agents |

| |

| Oils |

| |

| Vegetable oils, vinegar, (oil in water emulsions) |

| |

| Enzymes |

| |

| Yogurts, creams |

|

Solutions in the Food and Beverage Industry

Illnesses and allergies from contaminated food are all too commonplace unfortunately. That's why food safety, recipe compliance, and process integrity are top priorities for LEWA equipment. With our products, you can process and homogenize food and guarantee your end customers the best quality as a result.

Thanks to their hermetic seals, our products and systems prevent cross-contamination and contamination resulting from abrasion. And the optimum cleanability that they offer helps here too.

This is ensured thanks to a hygienic design that complies with national and international guidelines and standards. Perfectly designed pumps and process-safe systems for homogenization, for example, guarantee recipe compliance and reliable quality in the end product – always reproducible and economical, even over long periods.

We work together in technical commissions with end users and official agencies to create and review guidelines. This allows us to focus our actions on the current needs of customers and ensure that our knowledge is always up to date.

Advantages at a Glance

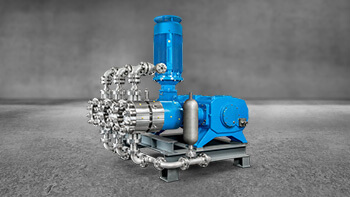

High end pumps, equipment and systems

We deliver high-end pumps integrated into complete systems and units for your specific applications. In doing so, we of course rely on the tried-and-tested LEWA quality.