Oil and gas industries

Used offshore and onshore all over the world

Customers across the globe put their trust in our products in the oil and gas production industry. From antifouling agents through to wax inhibitors – with our pumps and custom packages, you know you are using chemicals safely.

Of course, our pumps also meter corrosion inhibitors, oxygen binders, and other toxic and corrosive substances without a problem and guarantee absolute process safety.

What is more, LEWA offers reliable solutions for high-pressure injection and sealless crude oil and natural gas production. Our systems can cope with the harshest environments: Whether in cold Siberia, the hot Arabian Desert, or on the rough sea – with LEWA products, you're guaranteed efficient and fail-safe processes.

Areas of Application in the Oil & Gas Industry

Whether for the conveyance or further treatment of raw materials – LEWA products and systems offer solutions for all processes in oil and gas production.

| Product applications | Chemicals | Purpose |

|---|---|---|

| Treating oil, gas, and water | Foam inhibitors | Reduce foam to ensure maximum flow rate |

| Asphalt inhibitors, antifouling agents | Prevent asphalt formation | |

| Biocides | Minimize the growth of aerobic and anaerobic bacteria | |

| Calcium nitrates | Prevent the formation of dissolved sulfides and H2S | |

| Corrosion inhibitors | Reduce corrosion in pipelines | |

| Demulsifiers, emulsion breakers | Split stable oil-water emulsions | |

| Oil separators/flocculants | Separate oil and production water | |

| Friction reducers, flow rate improvers | Reduce friction losses in pipelines | |

| H2S binders | Prevent corrosion by hydrogen sulfide | |

| Hypochlorites | Prevent the growth of organisms | |

| Hydrate inhibitors with low density/LDHI | Hydrate inhibitors with low metering rate | |

| Oxygen binders | Remove residual oxygen | |

| Paraffin inhibitors | Prevent paraffin formation | |

| PH control agents | Reduce glycol decomposition | |

| Polyelectrolytes | Filter aids | |

| Crust inhibitors, crust reducers | Prevent process equipment crusting | |

| Clarifiers for water | Remove oil particles in production water | |

| Wax inhibitors | Prevent wax formation | |

| Solar-powered systems for injecting chemicals | Corrosion inhibitors, methanol | Inject chemicals in remote and unmanned production sites or pipelines |

| Gas-powered systems for injecting chemicals | Corrosion inhibitors, methanol | Inject chemicals without emitting (acid) gas in remote or unmanned production sites or pipelines |

| High-pressure injection | Carbon dioxide CO2 | Injection underground |

| Hydrogen sulfide H2S | Injection underground | |

| Methanol/ethanol | Prevents the formation of hydrate in gas production sites | |

| Glycol (MEG/TEG) | Gas dehydration | |

| Sealless conveying | Condensate | Leak-free pumping of separated product with low feed pressure (high vapor pressure) |

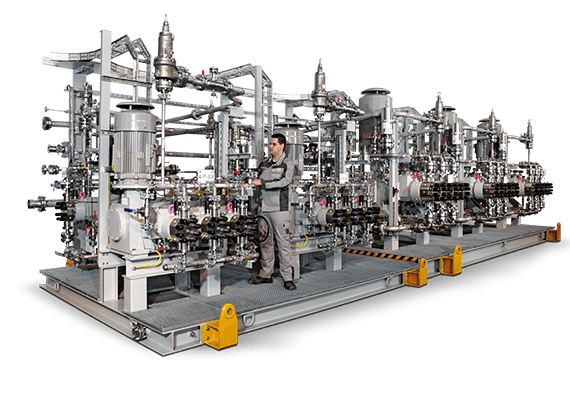

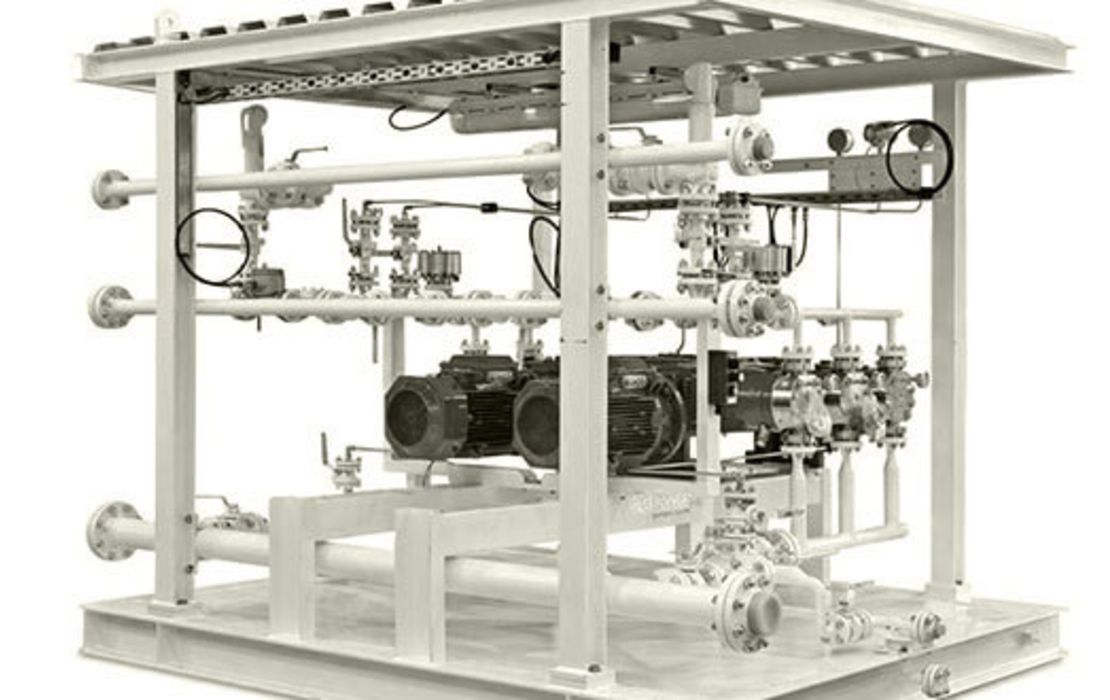

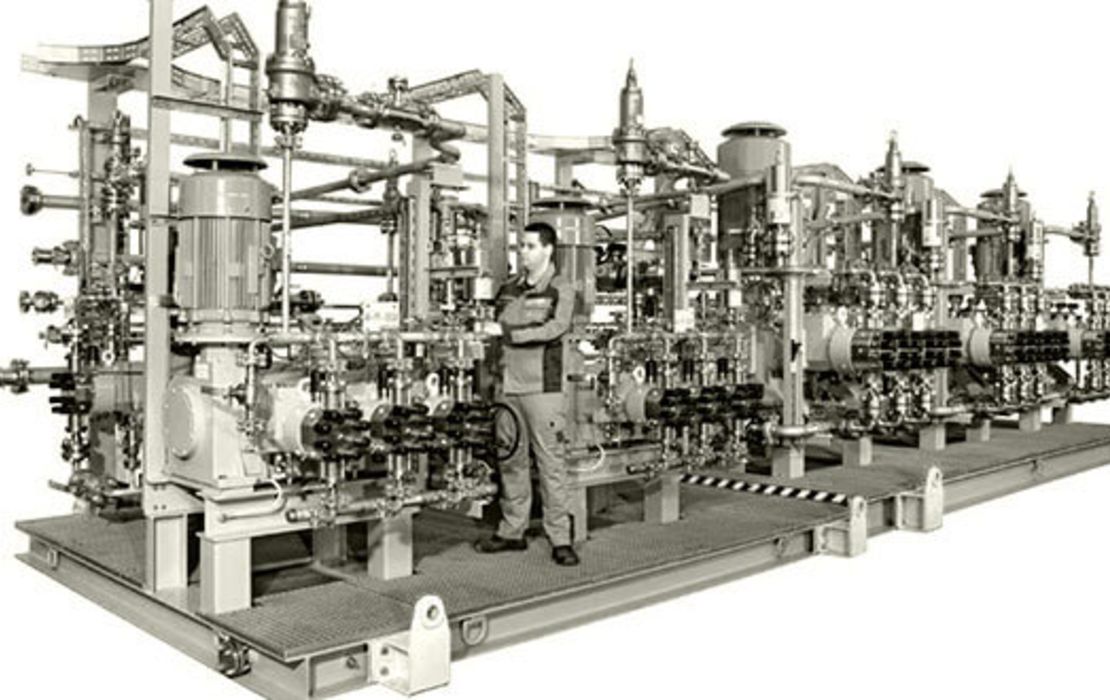

Solutions for the Oil & Gas Industry

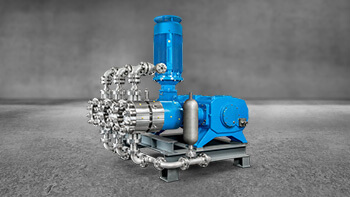

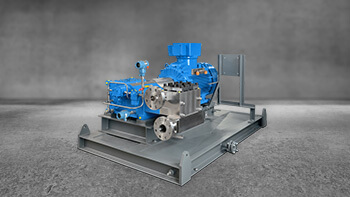

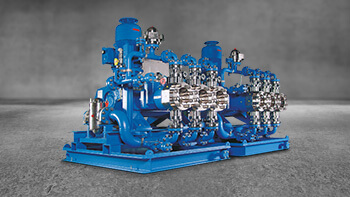

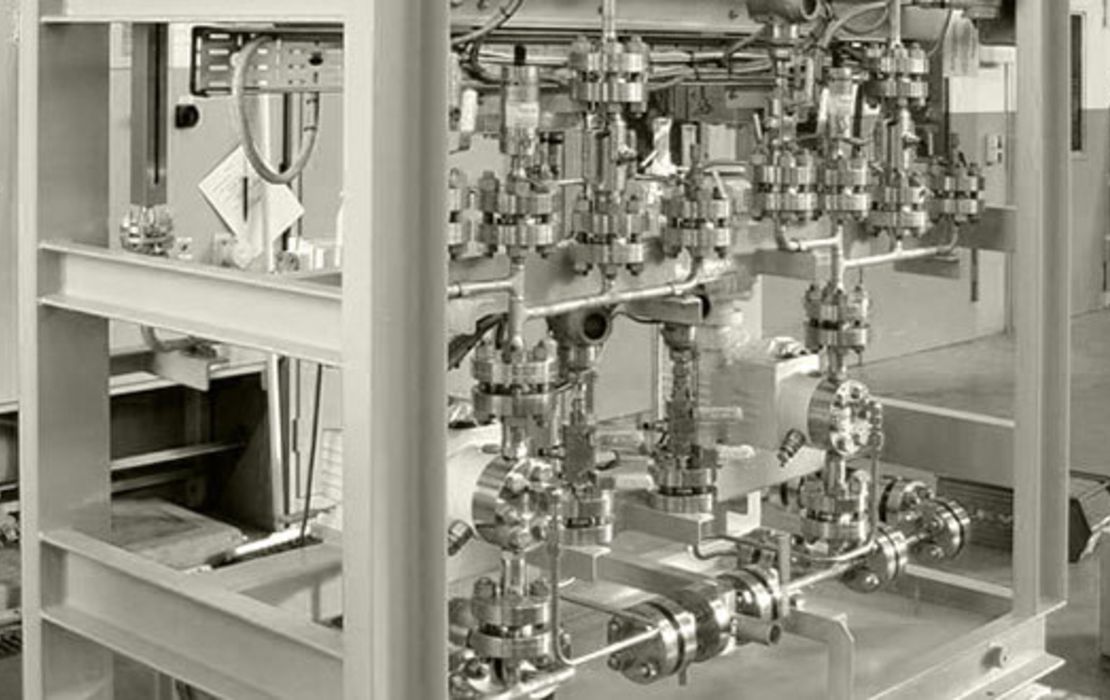

Count on an experienced supplier – LEWA! Our qualified equipment for natural gas production allows us to comply with all requirements in the oil and gas industry. We offer EPC companies, operators, and end customers our complete portfolio of high-end diaphragm and plunger pumps.

When developing pumps for extracting crude oil and natural gas, we take industry standards as well as your requirements and circumstances into consideration. High pressures, hermetically sealed units, and extreme safety in a compact design are a matter of course for LEWA. We offer you a safe tool for natural gas production in the form of our pump head, for example, which features a PTFE diaphragm for pressures up to 1000 bar and ensures maximum cost-efficiency!

Our many years of experience mean that we are able to offer international engineering and project expertise to assist you in all phases of your project.

Advantages at a Glance

High end pumps, equipment and systems

We deliver high-end pumps integrated into complete systems and units for your specific applications. In doing so, we of course rely on the tried-and-tested LEWA quality.

Spare parts information in your language

You will get all available information about spare parts (including subcontractors) in your preferred language. Our spare parts service functions quickly and smoothly.