Personal Care

Precise Results and High Quality with LEWA

Processes with strict quality and hygiene requirements, such as GMP or the production of personal care products without the use of preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for manufacturing personal care products.

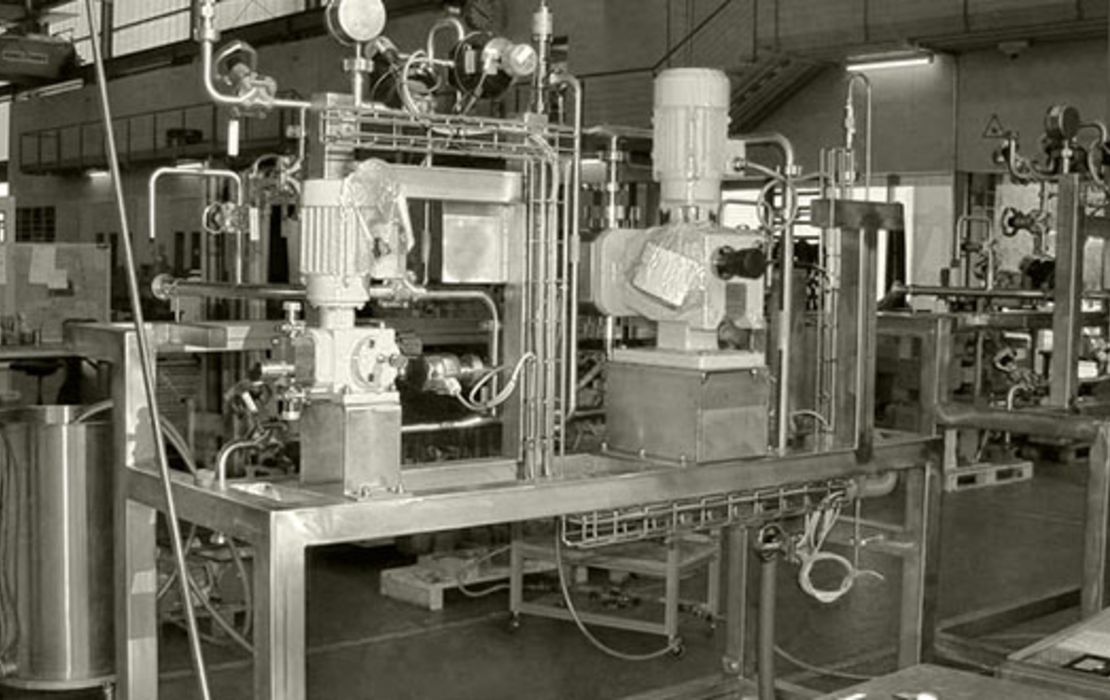

We create systems in accordance with your requirements and develop custom-made, integrated, efficient, and tested solutions that are designed for the durable, continuous production of your personal care products. To do so, we draw on our many years of experience in working with various fluids and materials and use our expertise in the areas of process and control technology.

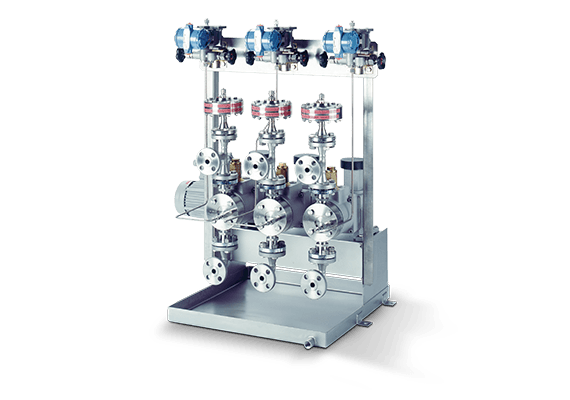

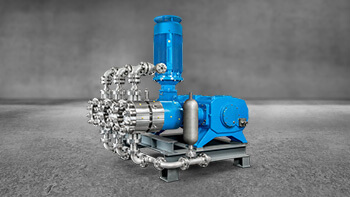

LEWA Pumps and Systems for the Production of Personal Care Products

Our experts are on hand with help and advice and will work with you to develop custom systems and plants for manufacturing personal care products. You can rely on our many years of industry expertise in various processes.

| Typical Applications for LEWA Systems | Process examples |

|---|---|

| Conveyance | Transporting rheologically challenging fluids (e.g., surfactants) but also simple transfer tasks |

| Metering | Adding fragrances and colorants, etc. |

| Mixing/dispersion/homogenization | Proportionally mixing base materials and active materials, producing emulsions, and formulating end products |

| Filling | Precisely filling containers |

| Tempering | Optimized procedure for continuous process (e.g., using heat recovery concepts) |

Our pumps and systems for the production of personal care products are used in various processes.

| Typical substances that we convey, meter, and process | Examples of end products |

|---|---|

| Solvents (Aqua), surfactants | Skin cleansers |

| Lipid components, nourishing ingredients | Skin care products |

| Titanium oxides | Dental and oral hygiene products |

| Colorants | Hair care products |

| UV filters | Cosmetic products with a special effect, e.g., sun protection products |

| Perfume oil | Perfumes and eau de toilette |

| Surfactants, moisturizers | Shaving products |

| Bulking agents, thickeners | Decorative cosmetics, body care products |