Pharmaceuticals, Life Sciences, and Biotechnology

Hygienic Mixing, Metering, and Dilution with LEWA Solutions

Special expertise is required in the production of pharmaceuticals in order to ensure that the legal requirements and regulatory are met.

Reliability when it comes to production, documentation, and validation are our top priorities. That's why you can rely on LEWA’s tried-and-tested pumps, pump packages and complete systems for many processes in the pharmaceutical, life sciences, and biotechnology industries. Our experts will be happy to advise you on finding optimum, customized solutions for your metering, purification, mixing, and filtration processes.

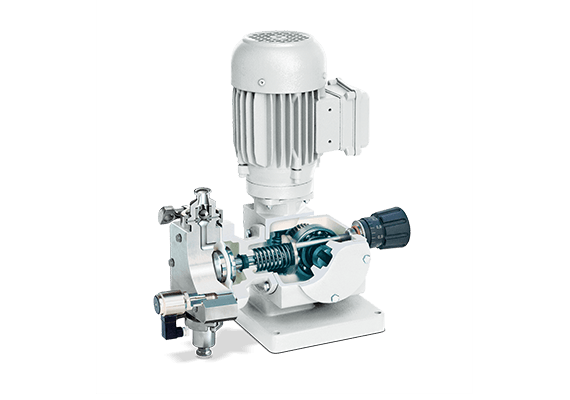

LEWA hygienic metering pumps (LEWA ecodos and LEWA ecoflow) meet all aseptic requirements in these processes and are always the first choice when it comes to manufacturing low bioburden or even sterile products.

Inline Dilution, Mixing, Dosing and Other Processes in the Pharmaceutical, Life Sciences, and Biotech Industries

Our systems have in-house engineering and meet all the industry-relevant requirements, such as for inline dilution and dosing (cGMP, GAMP, 21 CFR, etc.). We also offer complete documentation, acceptance tests, validation/qualification, installation, and commissioning services.

System solutions from LEWA can be found in many applications in this market: from the metering of liquids, production of dispersions, homogenization processes at high pressures, various mixing tasks, processes for the dilution of buffers or handling product or concentrates right through to the diverse DSP unit operations. These tasks require precise volume flows and exact conformance with specific process conditions.

| Product applications | Task | Process/System |

|---|---|---|

| Areas of application for our products and solutions in the pharmaceutical and biotechnology industries | Proportionally mixing sensitive, expensive fluids on a continuous basis | Metering additives for tablet production; tablet coatings, preservatives |

| Precisely adding fluids during the chromatography process | Dosing fluids into the purification process, diluting buffers and concentrates | |

| Metering sensitive fluids | Adding enzymes, vitamins, flavorings, and additives for fermentation | |

| Aseptically transferring proteins and cells | Adding micro-organisms to fermentations, transferring blood or blood components, transferring products in filling processes | |

| Adding additives | Additives, toxic chemicals | |

| Injecting fluids for extrusion or spraying mechanisms | Producing active ingredients and tablets, adding stabilizers | |

| Microfiltration and ultrafiltration, dialysis systems | Filtering process solutions, carefully concentrating intermediate products (biopharmaceuticals), concentrating and purifying protein solutions, separating cells and particles | |

| High-pressure and supercritical applications | Dispersing 2 phases, supercritical processes with CO2, generating nanoparticles |

Solutions for the Pharmaceutical, Life Sciences, and Biotech Industries

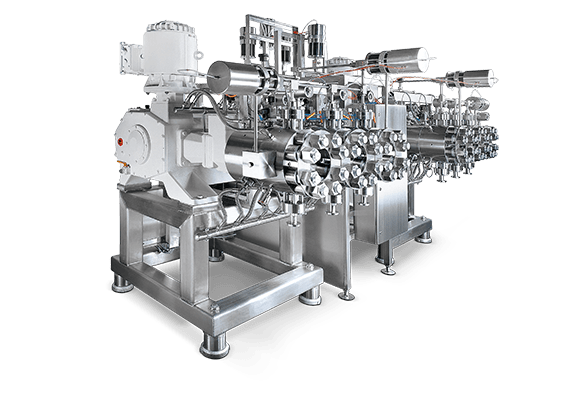

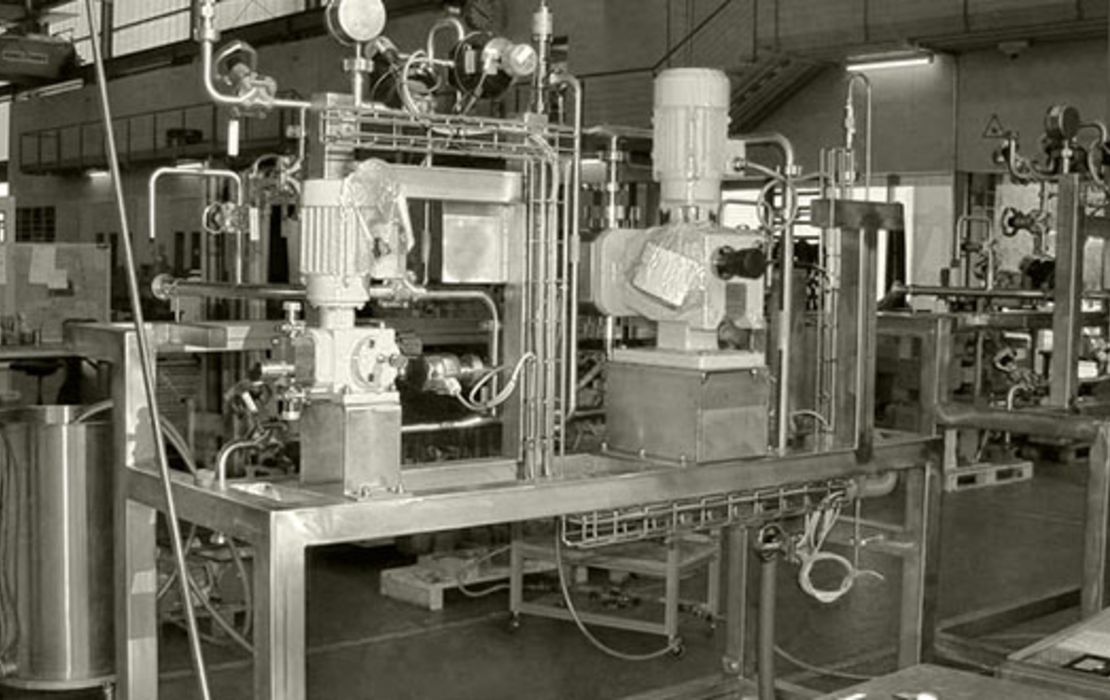

The biopharmaceutical, fine chemical, veterinary medicine, and special food supplement industries all require systems that are easy to clean and drain, and that are manufactured and documented according to the applicable guidelines. LEWA has the expertise to design and construct customer-specific systems for these industries.

Our scope of supply for these sectors ranges from simple metering systems for metering additives, dosing modules in process chromatography units and buffer dilution systems, right through to complex systems for the proportional mixing or conveyance of various media.

Process-Integrated Pump Systems for Filtration and Other Processes

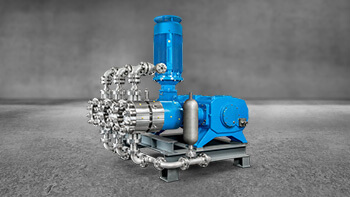

We also use the LEWA intellidrive technology to solve difficult metering and conveying tasks:

- Applications that allow a minimum of pulsation such as sensitive chromatography media or fluids during filtration processes

- Highly viscous fluids such as syrup or gel

- Highly precise metering during filling jobs

- Hermetically sealed for hygienic and sterile processes

- Mixing of two fluids in one pump head such as gradient formulation in chromatography processes

- At varying flow rates and at inhomogeneous qualities, changing pressures, or temperatures

Metering Pumps in Hygienic Design

LEWA hygienic metering pumps (LEWA ecodos and LEWA ecoflow) are hermetically sealed, leak-free, and have no connection, such as a shaft, to the product space. This ensures contamination-free metering and conveying over a long process time frame.

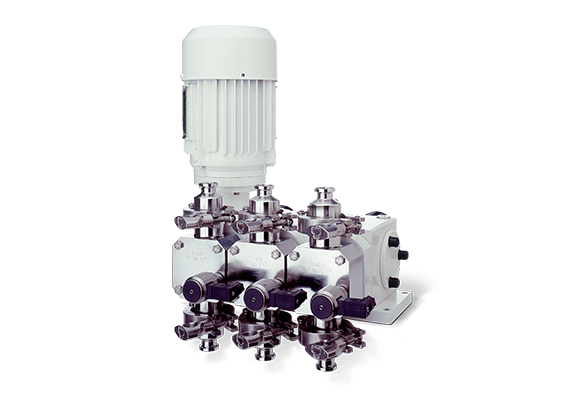

Hygienic pumps can also be used as multiplex pumps (e.g., for metering formulas). This means that several pump drive units can be assembled on one drive shaft. The individual pumps then convey varying quantities into the process. To increase the safety of your aseptic and sterile production processes, LEWA hygienic pumps are tested for their cleanability according to recognized, internationally valid guidelines (EHEDG cleanability test and QHD test system).

Advantages at a Glance

High end pumps, equipment and systems

We deliver high-end pumps integrated into complete systems and units for your specific applications. In doing so, we of course rely on the tried-and-tested LEWA quality.