Plastics

With LEWA Products Throughout the Production Process

LEWA supplies pumps and systems to support you in the many different production steps involved in plastics processing. We assist you in the processing of polyethylene, polypropylene, polyurethane, and polyamide. What's more, we also supply you with metering systems for compounding as well as for catalyst and foaming agent metering.

We offer you special expertise for all compounding processes in the plastics processing industry such as the addition of waxes, flame retardants, and lubricants.

Areas of Application in the Plastics Processing Industry

Our experts are on hand with help and advice and will work with you to develop custom metering solutions. Our expertise in polyethylene processing in particular is in high demand worldwide.

In the following table, you can see applications for the metering of reactants and catalysts.

| Examples of reactants and catalysts | Examples of plastics |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LEWA supports you in the further processing and refining of plastics. This includes compounding, i.e., during the addition and metering of flame retardants and lubricants, plasticizers, colors, antistatic agents, and other additives for property optimization, as well as foaming agent metering during foam extrusion.

| Base plastic | Examples of products |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Solutions for Plastics Processing

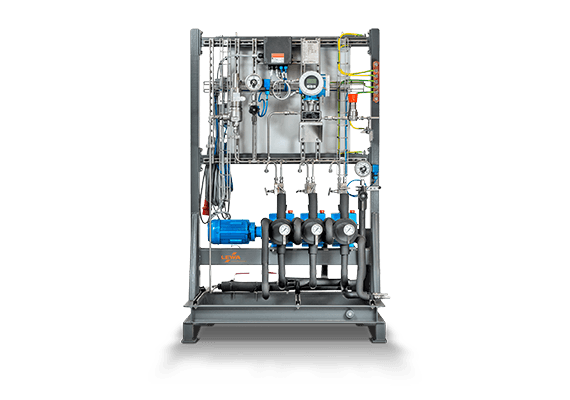

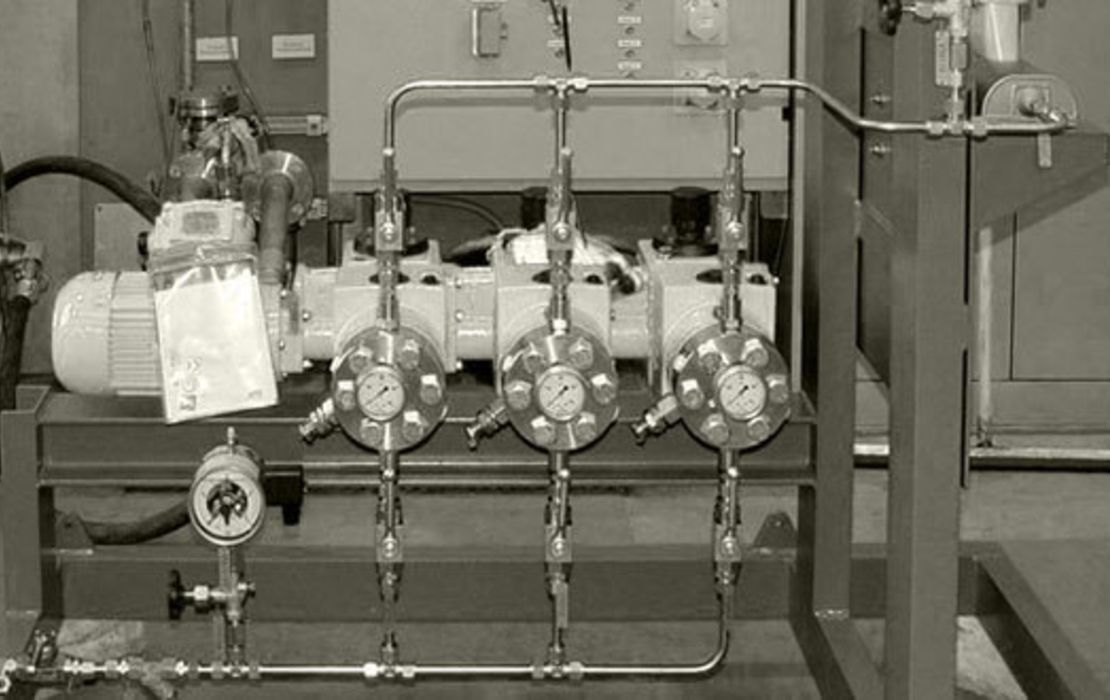

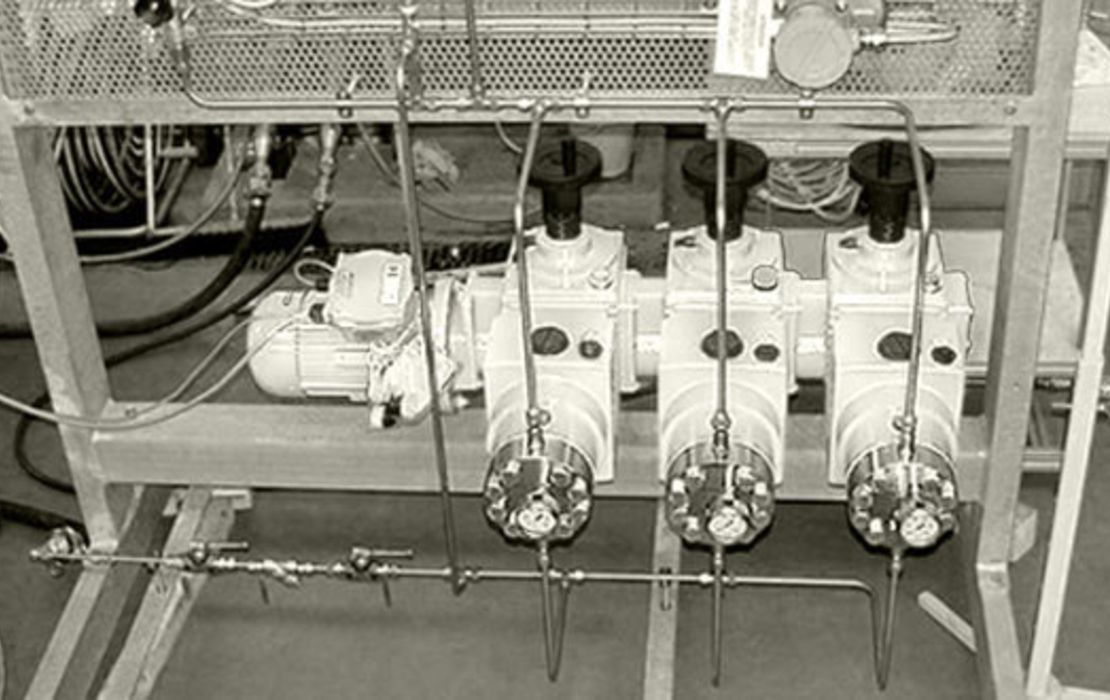

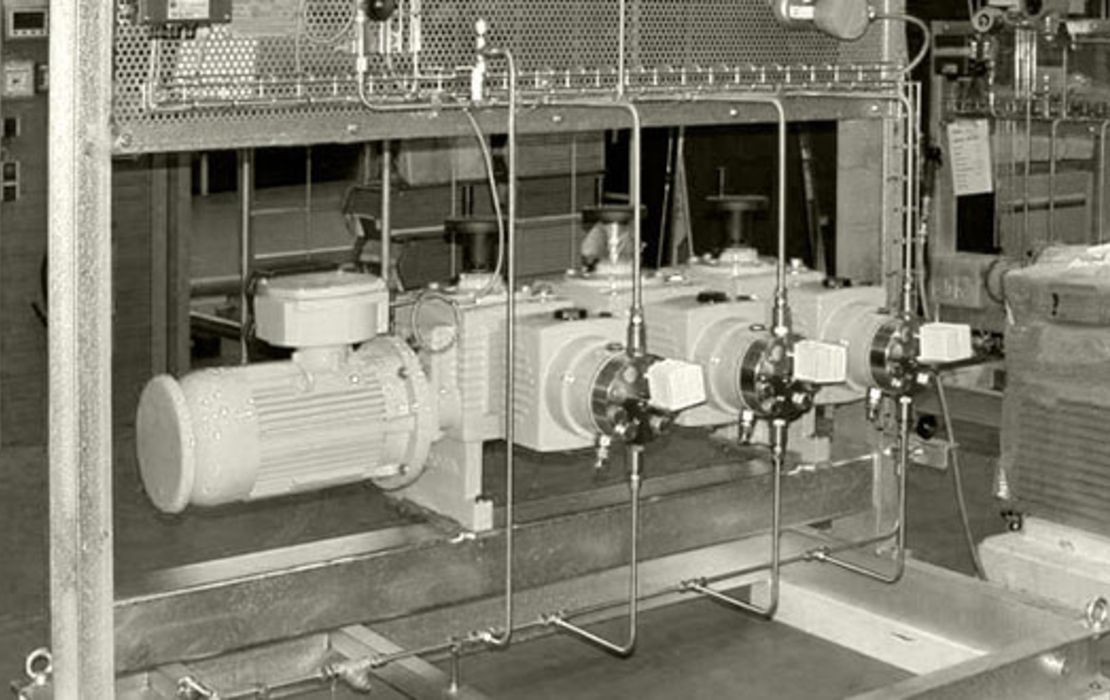

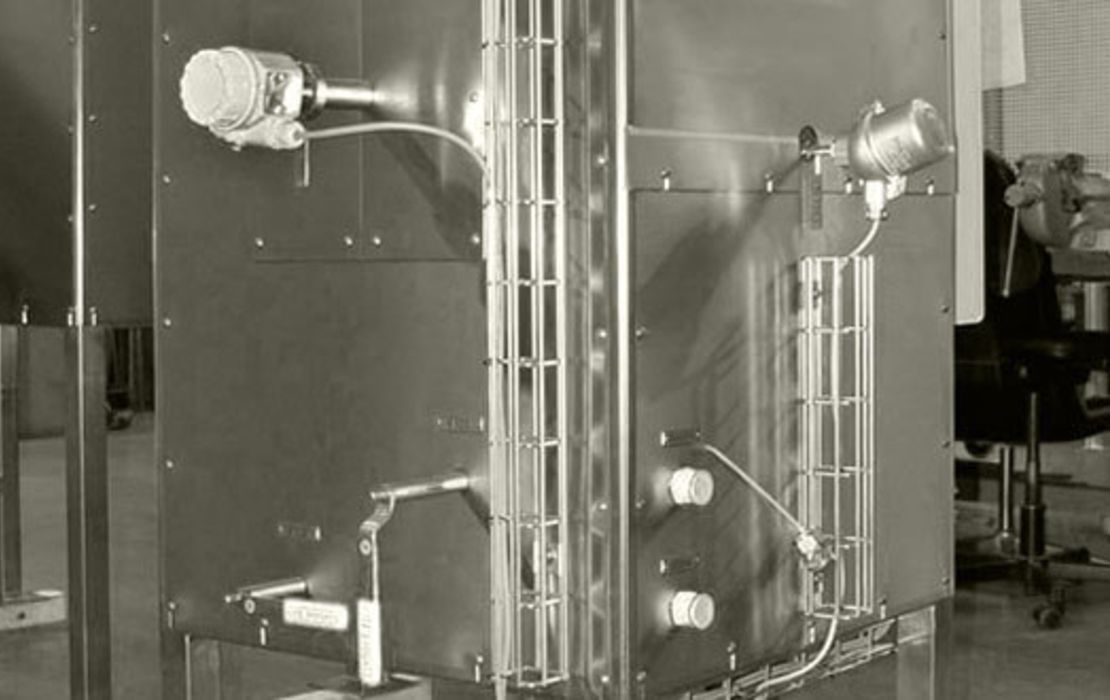

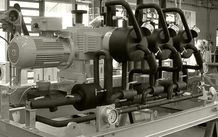

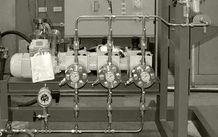

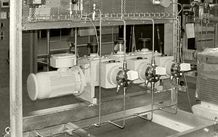

Our LEWA ecofoam system provides a tested and modular metering system for your specific application in the field of physically foaming polyolefins such as polyethylene processing.

This system is used worldwide by leading manufacturers and is characterized by controlled and exact metering. Not only does this ensure that the foamed product is always of a consistently high quality, it also significantly reduces scrap.

Advantages at a Glance

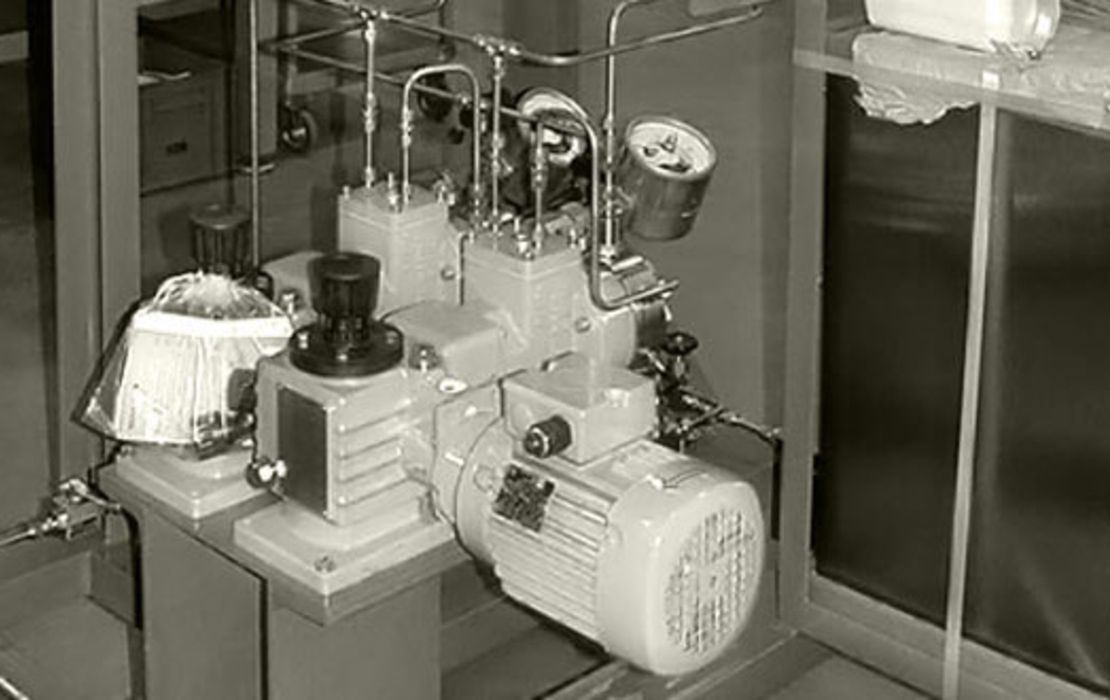

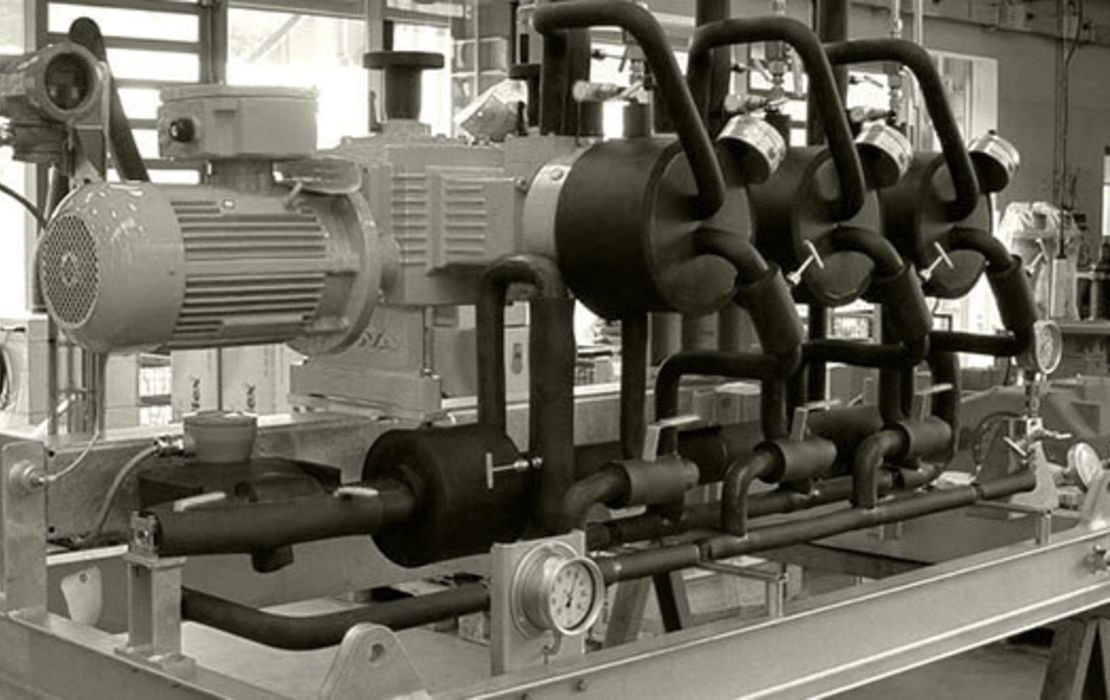

High end pumps, equipment and systems

We deliver high-end pumps integrated into complete systems and units for your specific applications. In doing so, we of course rely on the tried-and-tested LEWA quality.