Individual solutions for your special application

LEWA process experts can help solve your application requirements. Our first key is to listen intently to your objectives and goals, which may include converting a batch process to continuous, optimizing an existing system, or designing a new concept.

Our process, mechanical, automation and design professionals simplify and optimize all aspects of the project, while creating a quality solution.

Service contracts individually tailored to the customer’s requirements and original spare parts increase the operational safety, reduce the operating costs and extend the service life of the plant.

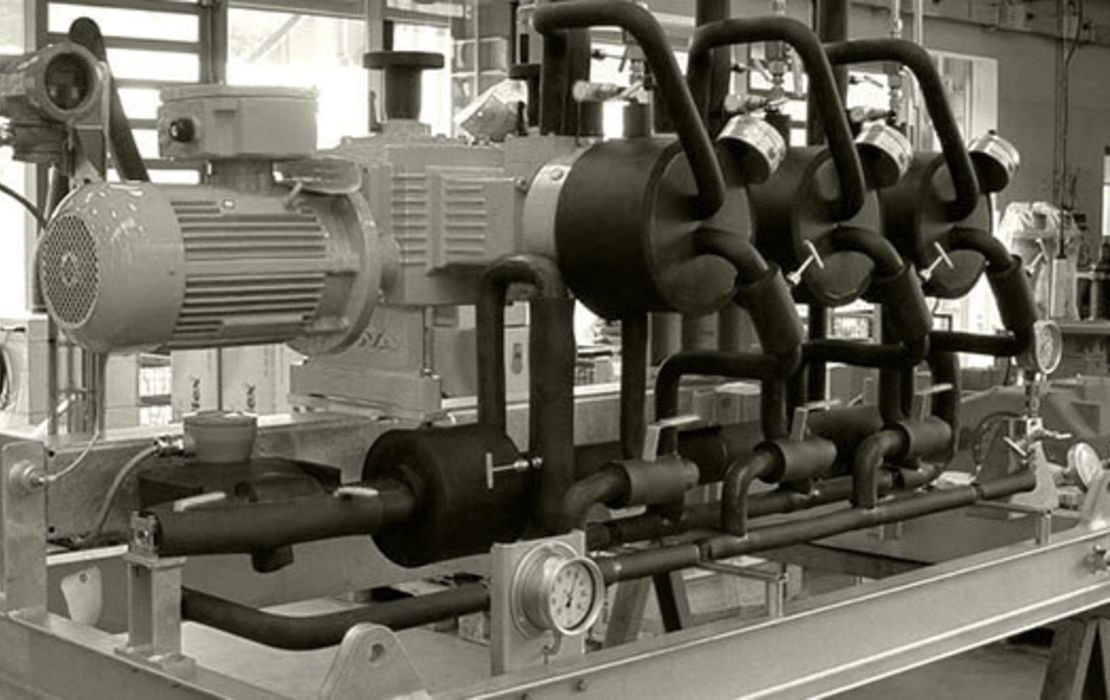

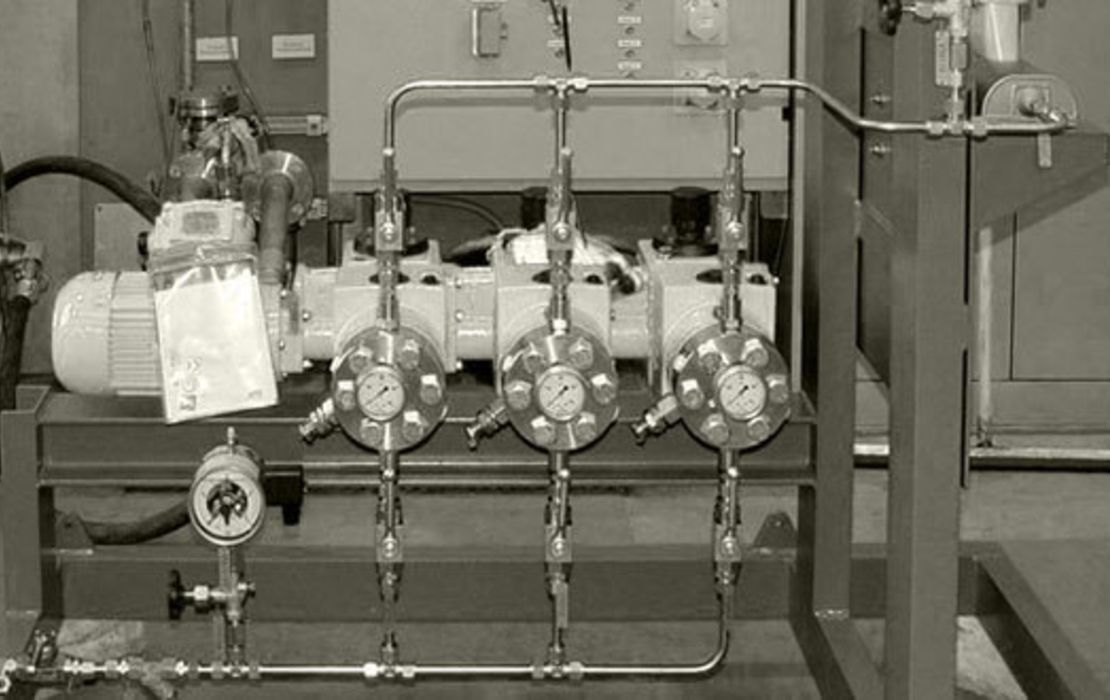

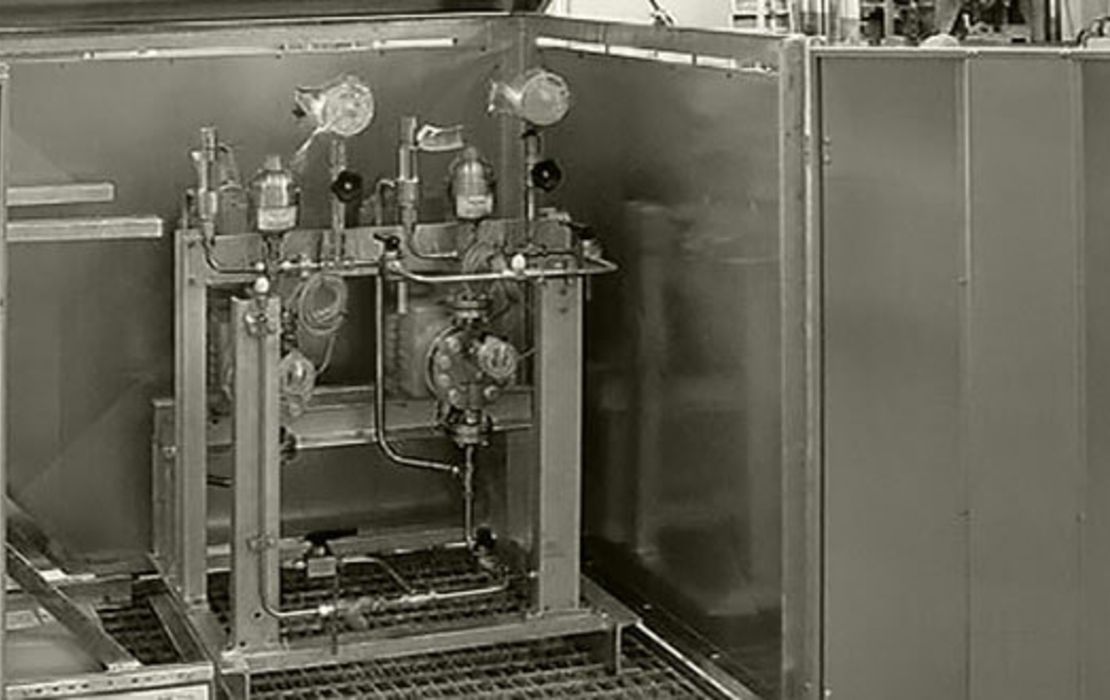

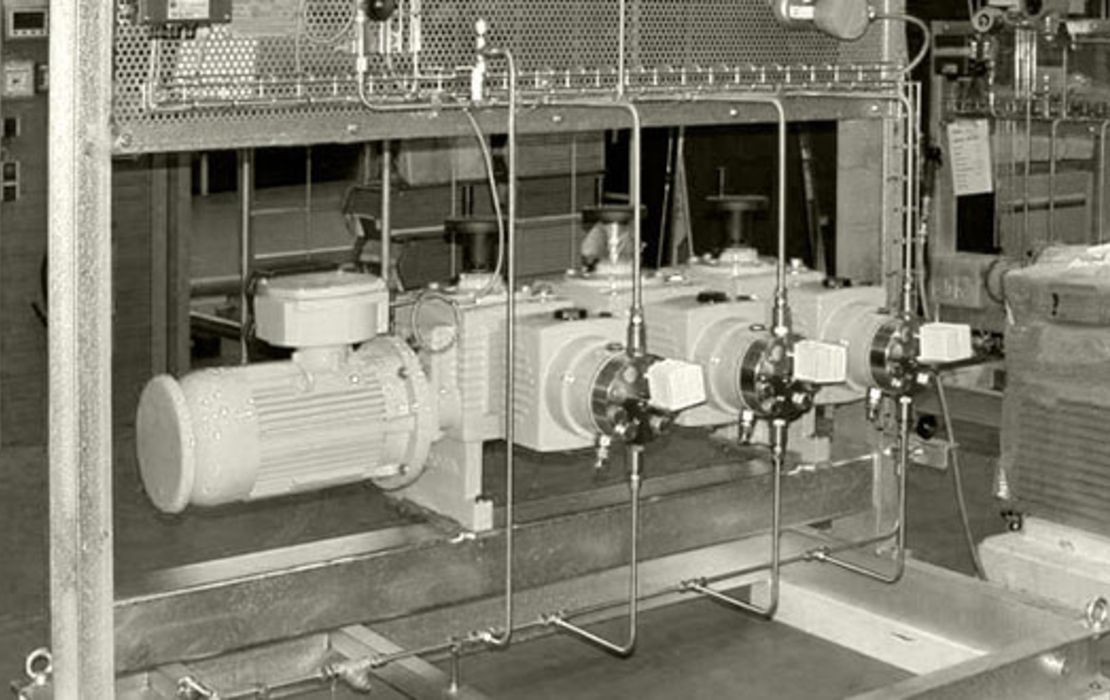

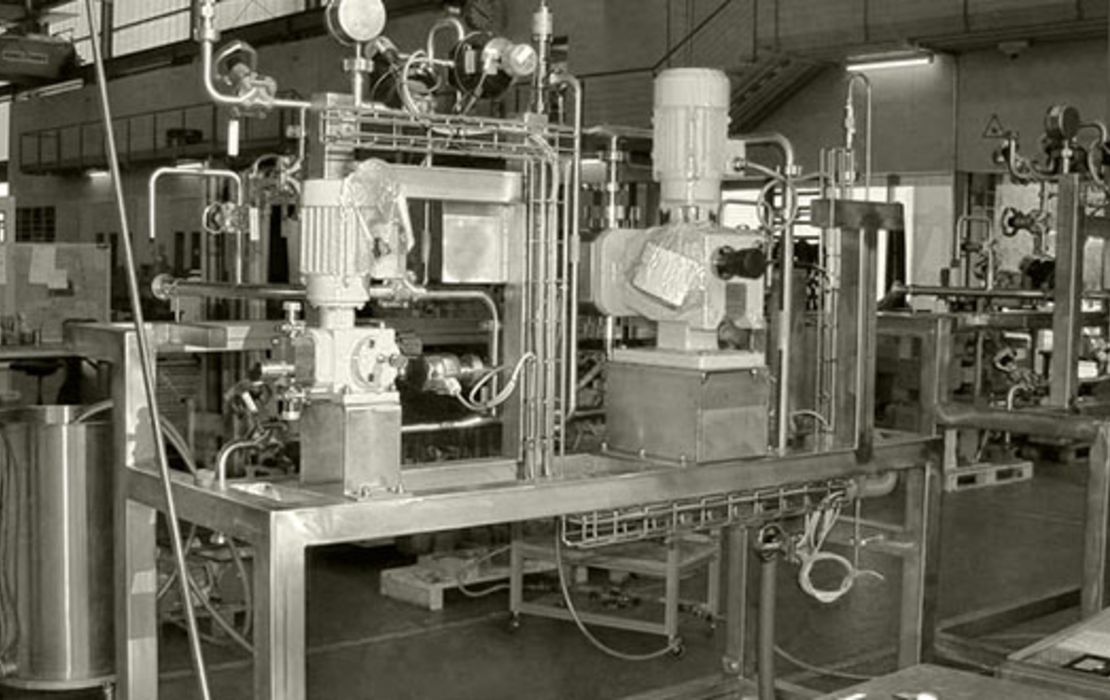

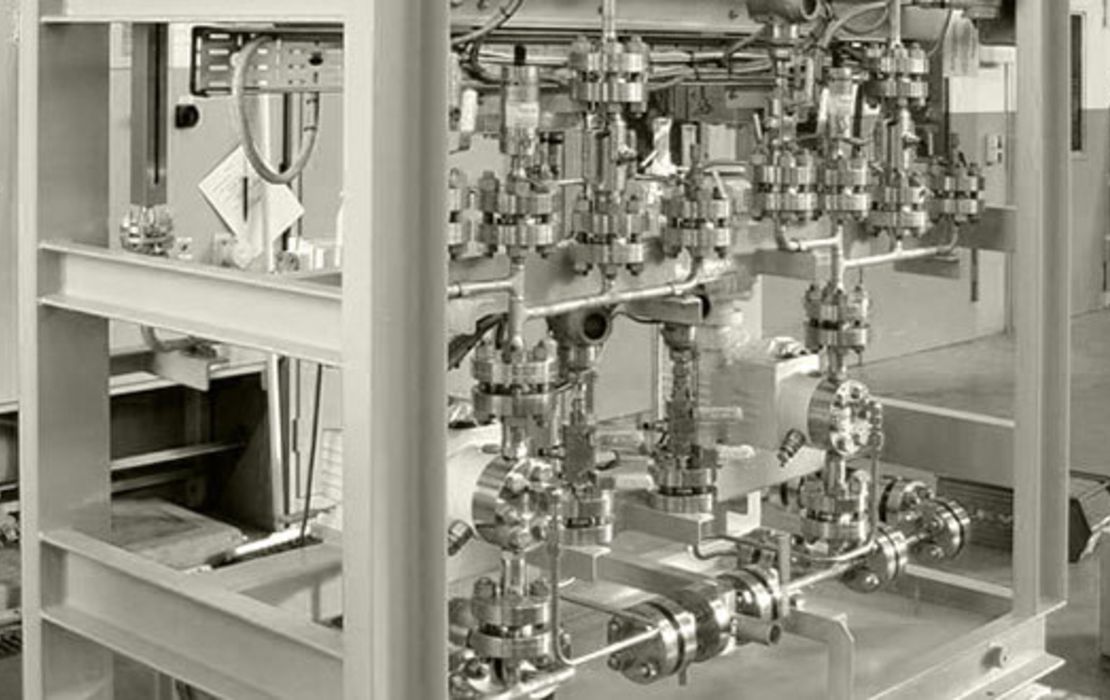

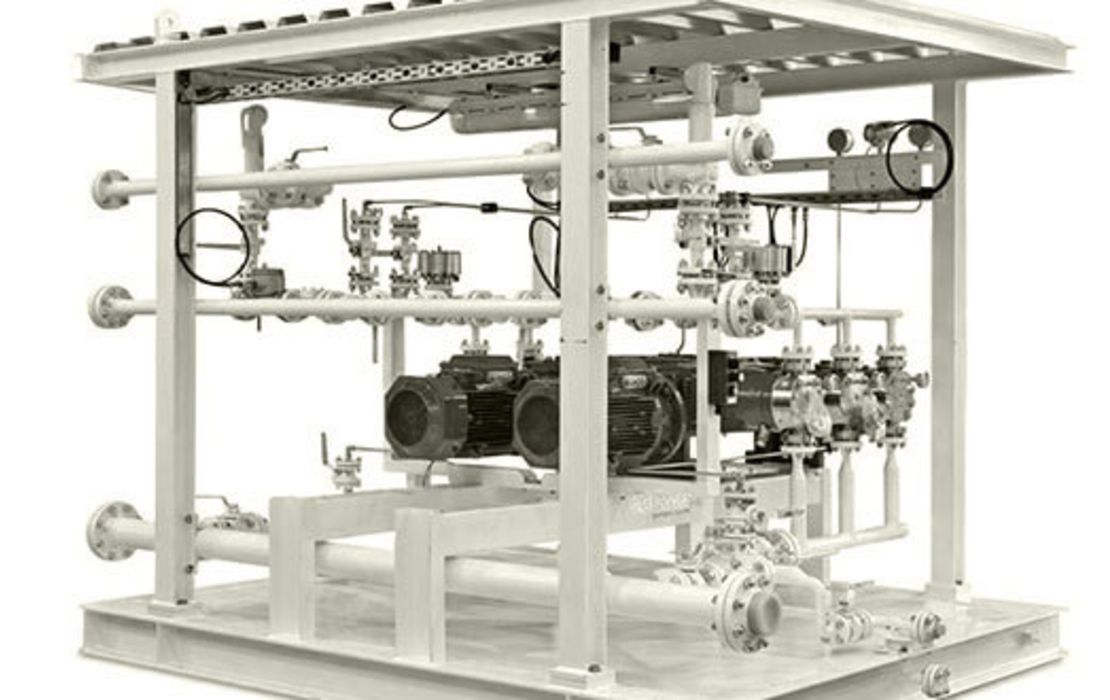

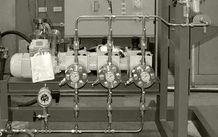

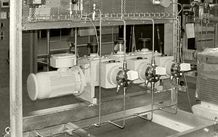

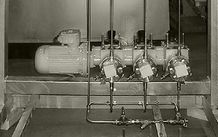

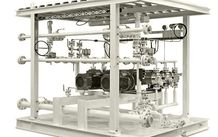

Individual pump configuration und state-of-the-art design

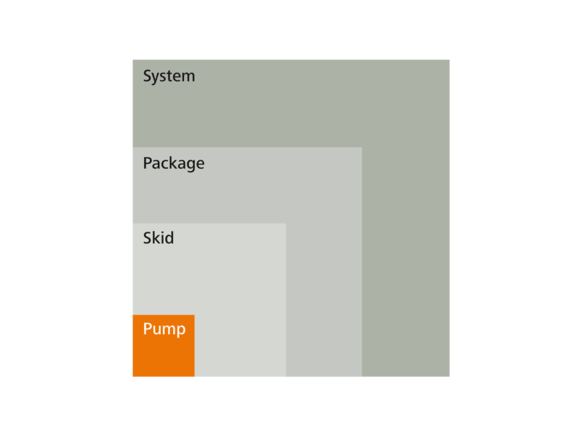

One of LEWA’s strengths is the design of customer specific solutions. In cooperation with the customer skids, packages or complete process systems are developed. This not only includes the mechanical design, but also the control protocols.

In addition to individual process parameters, the design is in line with the corresponding requirements of the guidelines in force, e.g. ATEX, DGRL (PED); VbF, WHG. All LEWA products go through strict quality checks.

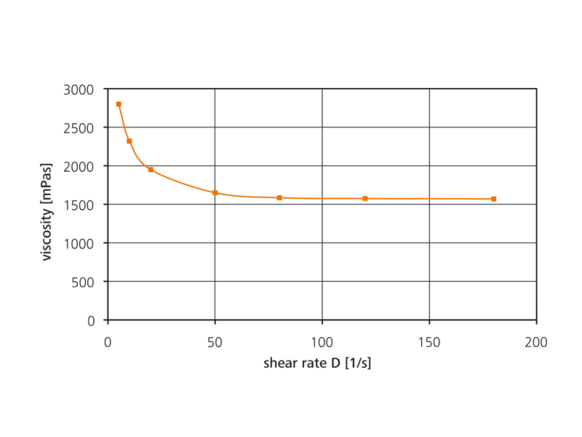

Fluid evaluations

Moreover the fluid evaluation offered by LEWA provides detailed information about whether and how the fluid can be metered. Thus recommendations can be given on the selection of the wetted materials, the pump design and also on the complete installation, which can save costs. All safety regulations e.g. for hazardous fluids are considered in these recommendations.

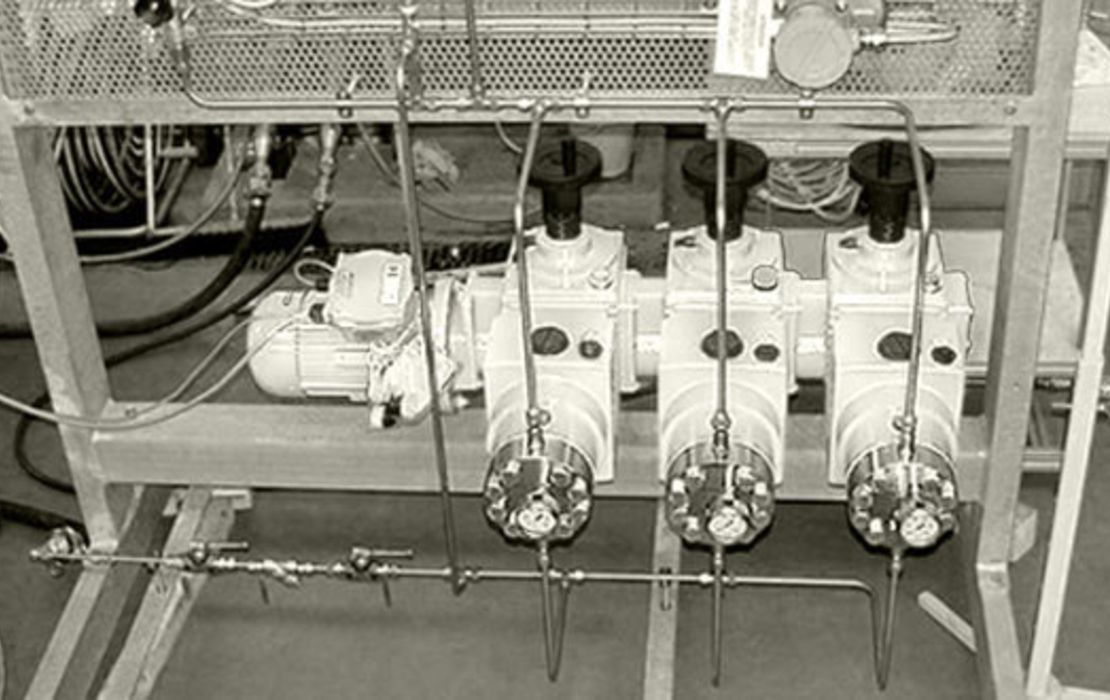

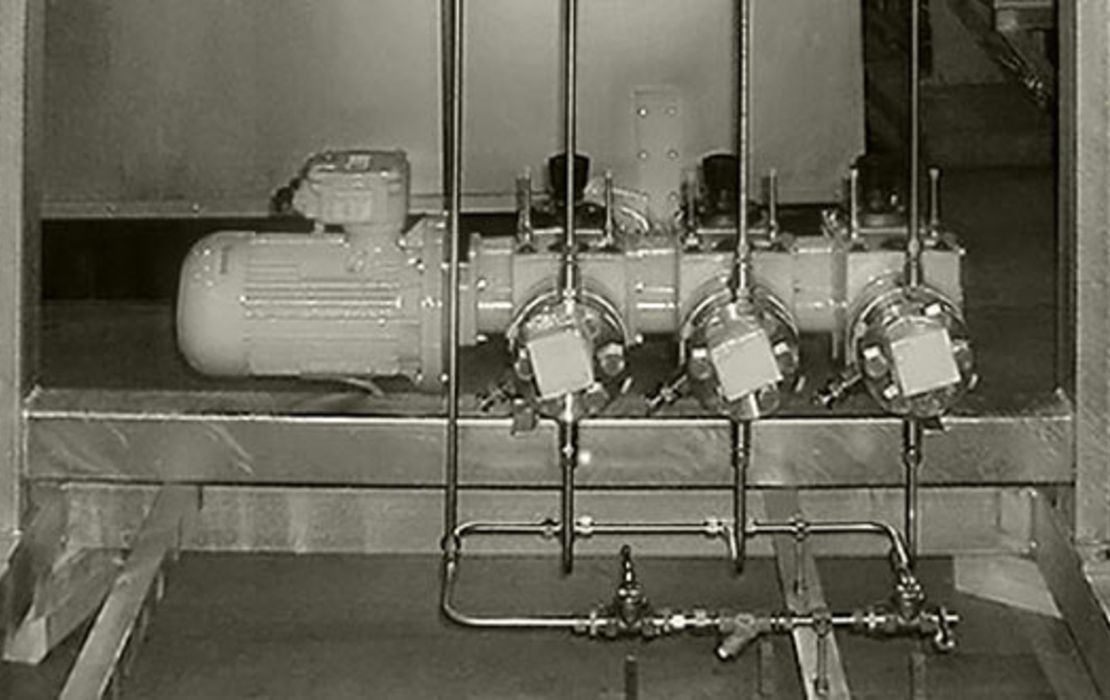

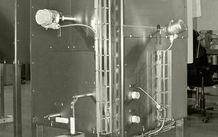

M900 diaphragm pump heads

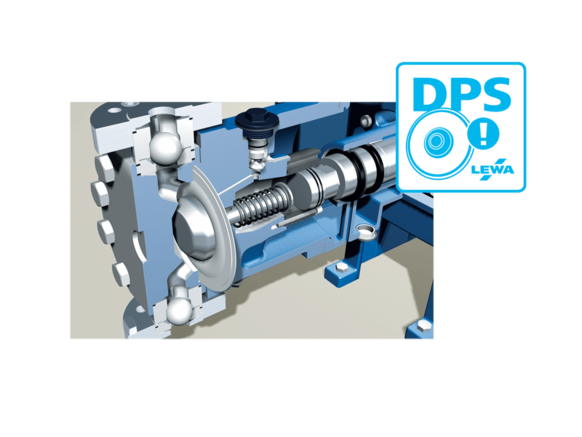

LEWA provides the most advanced diaphragm metering pumps in the world with maximum security for both production and the environment, primarily through the unique DPS (Diaphragm Protection System)* used for the ecoflow and ecosmart series.

The DPS system assures safety, even under extreme operating conditions, like high suction pressure or closed suction line. The internal overpressure protection is assured by a integrated pressure limit valve..

LEWA diaphragm pump heads are the safe and hermetically tight alternative for medium to high pressures. They present the economical solution for a variety of metering applications.

Ecologically damaging, dangerous, sensitive or abrasive fluids today are metered with zero leakage diaphragm pumps only. Any diaphragm damage is displayed reliably. In spite of this the pump remains tight and operation can continue for a limited time.

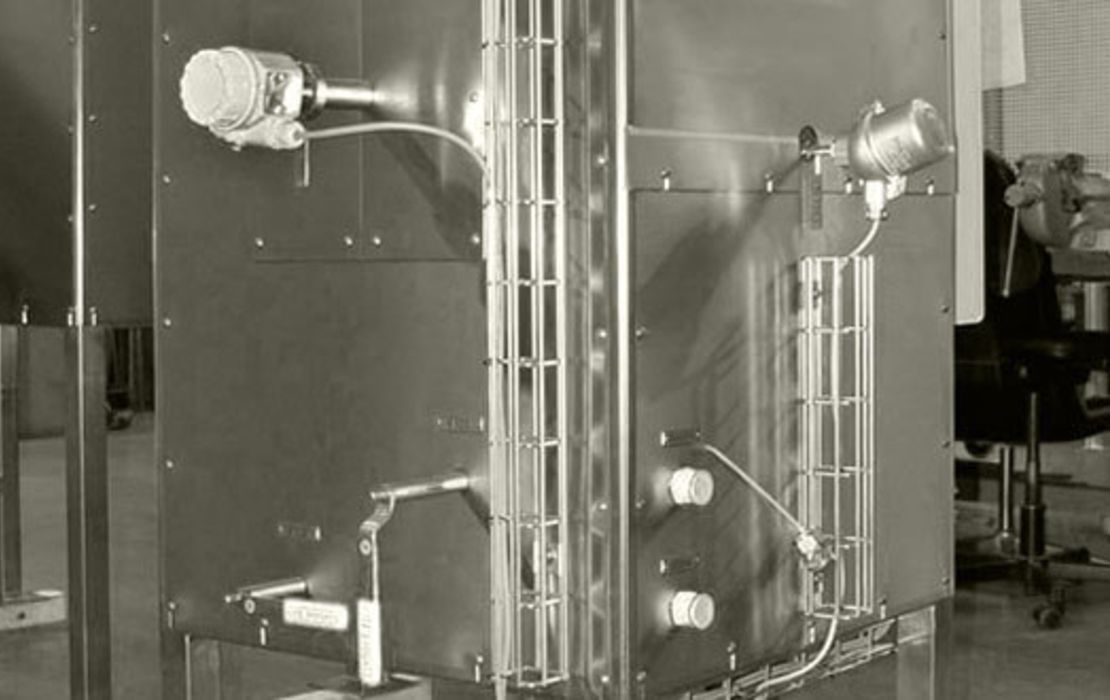

Piping calculations

To assure proper function of the pump in the plant, the interaction of the reciprocating positive displacement pump and the pipelines connected to it, must be considered in the early stages of development.

With our software “Pump Design” specially developed for LEWA pumps, we can check the installation for cavitation / overload and excessive metering, as well as resonance, taking the properties of the fluid into consideration. If required, optimizing measures for pipeline dimensioning, pulsation damping etc. are proposed. If requested, a full pulsation study can be provided.

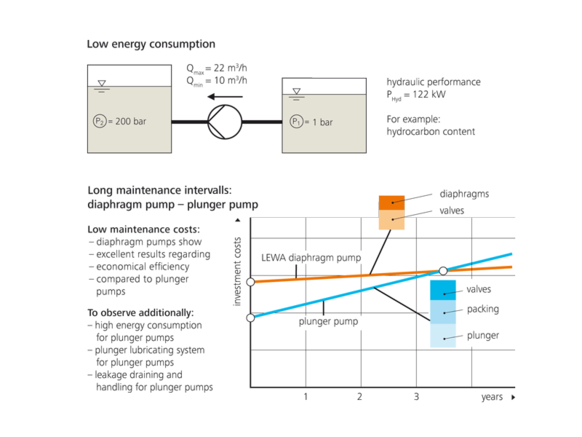

Long service life and high reliability with low maintenance costs

LEWA develops pumps and systems for high availability (annual continuous operation 8,000 h) and for a service life of over 25 years. Assuming continuous operation over several years, we calculate - even for process pumps under extreme operating conditions - total downtime of at most 3 days.

In other words: LEWA assumes an availability of up to 99 %. Given normal operation, the operator can expect these service lives for the most important components:

- Diaphragms, e.g. PTFE: up to 20,000 hours

- Pump valves: up to 20,000 hours (depending on design and application)

Our definition of customer benefit includes more than just technical features and high standards for quality. A critical core expertise of LEWA is the worldwide service and spare parts support. Through ongoing training of the entire personnel in the global after sales organization the customer can count on speedy and expert support in the event of a problem.

Apart from the global assistance for packages and systems during assembly and commissioning, economical modernization or optimization concepts are also developed together with the customer (e.g. Register your pump, Health check).

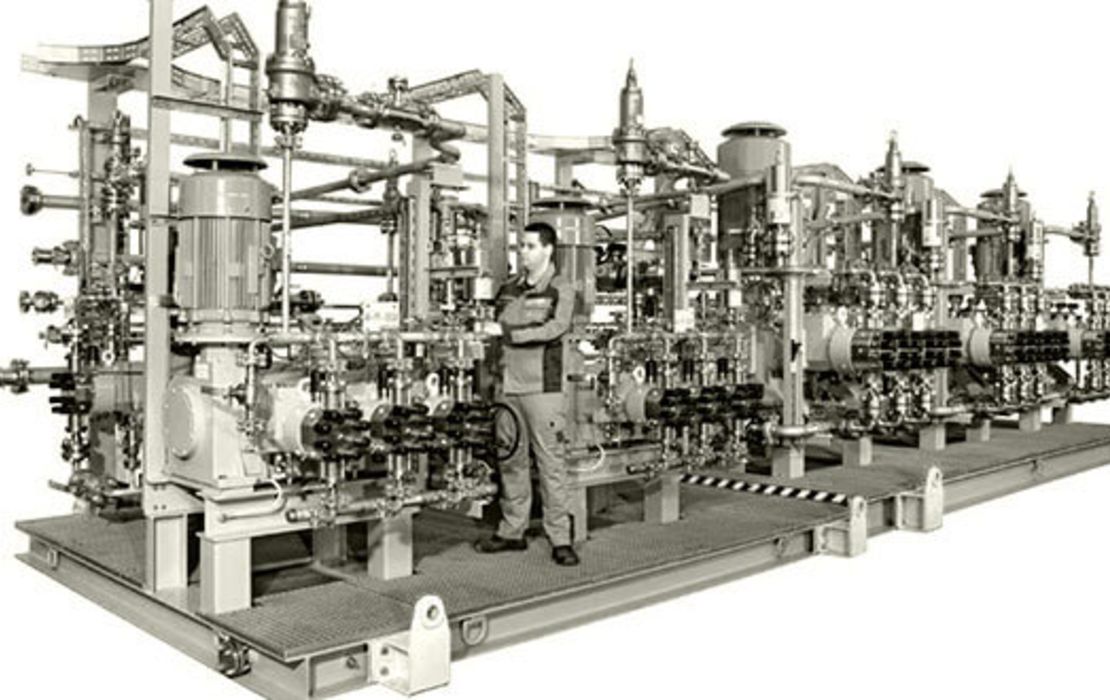

International engineering and project competencies

Customers worldwide benefit from LEWA’s experience and expertise which stretches back for over 50 years: If the customer manufactures in China for instance, the LEWA consultant is familiar with the relevant certificates and documentation in the Native language. If the EPC is based in the USA, the local branch can coordinate with engineers and operators onsite about process details. If the company is trading in Singapore, LEWA also has a branch there. The same applies to the Middle East, Africa, South America, Australia or every other distant part of the world.

LEWA project management covers the world of planning, construction, building and installation; the capable commissioning as well as the briefing for customers’ staff members and later the regular maintenance and supply of spare parts even in remote areas of the world.

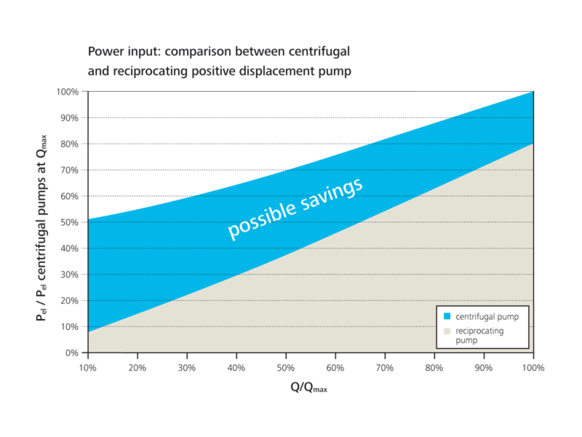

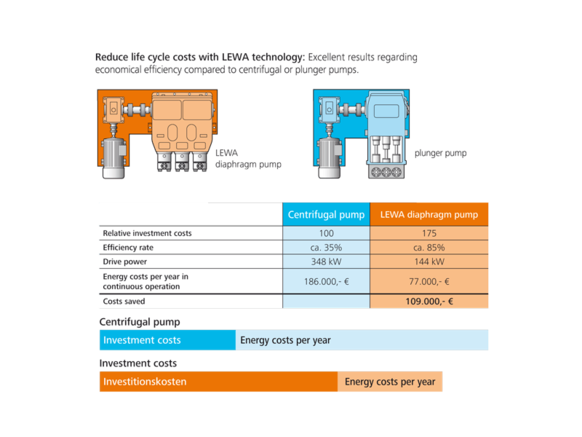

Low lifecycle costs

To this day, many system operators base their decision for purchasing a new pump solely on the purchase price, even though the majority of costs arise later on. Aside from the initial investment costs, operators should therefore particularly take energy consumption, operating expenses as well as maintenance, downtimes and resulting production losses into consideration when determining the overall life cycle costs of a metering pump. When it comes to small and medium-sized metering pumps, differences with regard to energy costs between different models or manufacturers are negligible. The primary focus for purchasing should, therefore, be maintenance costs and possible production losses.

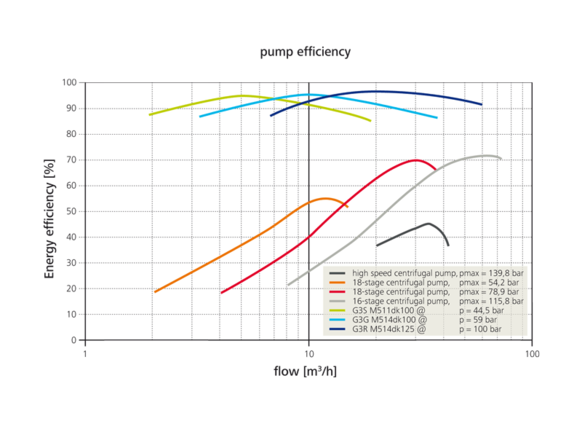

More efficient, environmentally friendly processes

LEWA products are often used for applications that allow more environmentally friendly processes and a more energy-efficient production. This is due to the fact that LEWA pumps amongst others have the best possible pump efficiency rate. For example, in CO2 re-injection in fossil waste disposal sites up to 35% of the energy costs can be saved, if LEWA pumps are used instead of compressors. This saving is possible because LEWA pumps have an efficiency of > 90 %.