Pulsation simulation

Reduced lifecycle costs due to optimal design.

With the LEWA installation inspection you already ensure during the planning stage that the entire system (pump with pipeline) will work reliably. Reduced investment costs based on optimal dimensioning and positioning of the components and long service life of the entire system are the results.

We discuss the basic requirements of an reciprocationg pump with you. Efficiency is all about the question of which components are required and how to arrange them. In addition, a detailed assessment of the liquid to be dosed is required for a professional assessment of the overall system.

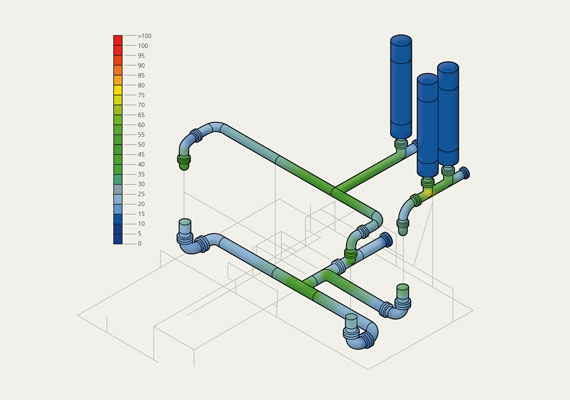

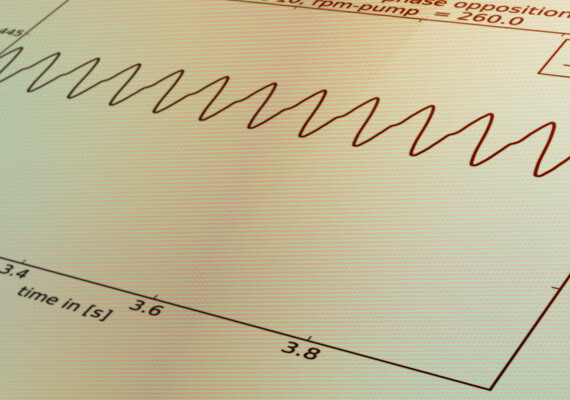

Pulsation studies

We perform an analytical study with our software PumpDesign. This provides information on:

- Mass pressure fluctuations, caused by the acceleration forces of the pump

- Volumetric pump efficiency

- Inlet pressure loss

- Minimum suction flange pressure

- Pressure loss and pressure pulsation in pipelines

- Cavitation and overload

- Resonance at critical speeds

We are the only pump manufacturer worldwide that also performs numeric simulations and test API 674 criteria. This will give you exact evidence, without any deouts to external institutions, on dynamic processes in complex pipeline systems (e.g., parallel operation of pumps) and pressure amplitudes.

These analyses are used for optimization of pulsation damping and pipeline dimensioning. In this way we prevent typical problems by exact calculation, such as cavitation and vibrations as well as fatigue damage to pipelines and components. The results of the study are summarized in a corresponding documentation.

Assessment according to API 674 and mechanical analysis

We offer this service as the world's only pump manufacturer. Without time-consuming detours via external institutions you get accurate information. In this case, the piping system is tested according to the following criteria:

- Comparison of the expected pressure amplitudes with the max. permissible values according to API 674

- Monitoring of the minimum pressure in the system to avoid cavitation

- Calculation of the distance between the maximum pressure in the system and the set pressure of the safety valve

- Sufficient distance of the pump excitation frequency of the mechanical resonant frequencies of the piping system

This results in clamping length recommendations. Considering the complexity of the system, the kinematics of the cylinders and the control range of the pump as well as the properties of the fluid we verify your installation.

If pulsation studies are done, there is the possibility of a further mechanical analysis. Detailed information on the piping fittings are required. The results provide information on the expected mechanical stresses, forces, torques, and deflections. You will receive a detailed mechanical assessment of your piping system. Possible optimization potential is demonstrated.